Thermal Foam Wall Panels: How They Improve Insulation

When discussing thermal foam wall panels, how they improve insulation is a topic that goes deep into building science. A foam panel is one of the most powerful tools for making a home energy-efficient, comfortable, and dry. But not all "foam panels" are the same.

Many people think of thin, decorative "peel-and-stick" foam tiles. Those are for looks.

This guide is about the real thing: thick, rigid, high-performance boards. These are the panels that lower your energy bills. We will explore the science of how they work, from R-value to the critical concept of "thermal bridging." We will compare the different types and explain how they stop heat, air, and moisture, all in one product.

What Are Thermal Foam Wall Panels?

Thermal foam wall panels are rigid, high-density boards made from plastic foam.1 They are used to insulate walls, basements, and roofs.2 Their primary job is to provide a high R-value and stop heat transfer. They are a structural building material, not a cosmetic, peel-and-stick tile.

It is very important to make this distinction.

- 3D Decorative Foam: Thin, soft, lightweight, and often "peel-and-stick." These are for looks. They have almost zero insulation value.

- Thermal Foam Panels: Thick (1/2-inch to 4-inches), rigid, and dense. These are for performance. They are a core part of a home's building envelope.

This article is about the high-performance thermal panels. For a general overview of all types, see our main guide on foam wall panels & insulation.

How Do Foam Panels Stop Heat? (The Science)

Foam panels stop heat through "thermal resistance." Their closed-cell structure is filled with a trapped gas. This gas is a very poor conductor of heat. This structure is also dense, which stops air movement (convection). Some panels even have foil-facing to stop radiant heat.

Heat moves in three ways. Foam panels are a "multi-tool" that can fight all three.

1. Stopping Conduction (Heat Transfer by Touch)

Conduction is heat moving through a solid object. A foam panel is, by design, a terrible conductor of heat. Its "closed-cell" structure is like a billion tiny, trapped bubbles. Heat cannot find an easy path through this "bubble-wrap" structure.

2. Stopping Convection (Heat Transfer by Air)

Convection is heat moving through the air. A draft is a perfect example. A great deal of energy is lost from air leaking out of your home. Rigid foam panels, when the seams are taped, form a continuous, solid air barrier. They stop air from moving through the wall.

3. Stopping Radiation (Heat Transfer by Waves)

Radiation is heat moving in invisible waves. This is the heat you feel from the sun or a hot fire. This is where Polyiso panels, which are foil-faced, really shine. The shiny foil reflects radiant heat, adding another layer of insulating power.

What Is an R-Value?

R-value is the standard measure of thermal resistance. It is the most important number in insulation. A higher R-value means the material is better at stopping heat flow. Rigid foam has a very high R-value for its thickness.

This is the metric you are "buying." The R-value is listed "per inch."16 For example, a 1-inch thick panel with an R-5 rating is a great insulator. A 2-inch panel of the same material would be R-10.

| Material | R-Value per Inch (approx.) |

| Polyiso Foam | ~ R-6.5 |

| XPS Foam | ~ R-5.0 |

| EPS Foam | ~ R-4.0 |

| Fiberglass Batts | ~ R-3.5 |

| Plywood | ~ R-1.2 |

This data shows why foam is so powerful. A 1-inch foam board can provide more insulation than a 3.5-inch thick piece of wood.

What Are the Main Types of Thermal Foam Panels?

The three main types of rigid thermal foam are EPS (Expanded Polystyrene), XPS (Extruded Polystyrene), and Polyiso (Polyisocyanurate).17 They differ in R-value, water resistance, and cost.18

Expanded Polystyrene (EPS) Explained

EPS is a white "bead-board" foam. It is made of thousands of small polystyrene beads fused together. It is the most affordable rigid foam. It offers a good R-value (R-4 per inch) but can absorb water over time if it is not protected.

- R-Value: ~ R-4 per inch.

- Appearance: White, with visible, fused beads.

- Cost: Low.

- Best For: Above-grade walls, roofs, and Structural Insulated Panels (SIPs). It is a great, low-cost choice for "dry" applications.

Extruded Polystyrene (XPS) Explained

XPS is a dense, closed-cell foam, usually pink or blue.19 It is made in a continuous "extruded" process. This creates a very consistent, smooth, closed-cell structure. It has a high R-value (R-5 per inch) and excellent water resistance. It is ideal for basements.

- R-Value: ~ R-5 per inch.

- Appearance: Pink or blue, smooth boards.

- Cost: Medium.

- Best For: Basements, foundations, and any "below-grade" or damp environment. Its closed-cell structure makes it a fantastic waterproof foam wall board.

Polyisocyanurate (Polyiso) Explained

Polyiso, or "Polyiso," is a high-performance foam with the highest R-value (R-6.5 per inch).20 It is almost always sold with a foil-facing on both sides. This foil facing acts as a built-in radiant barrier, which is a major bonus.21

- R-Value: ~ R-6.5 per inch.

- Appearance: Yellow foam core with a silver, foil-faced exterior.

- Cost: High.

- Best For: Roofs, attics, and exterior walls.22 It is the best choice when you need the most insulation in the thinnest possible panel.

The Real Secret: What Is a Thermal Bridge?

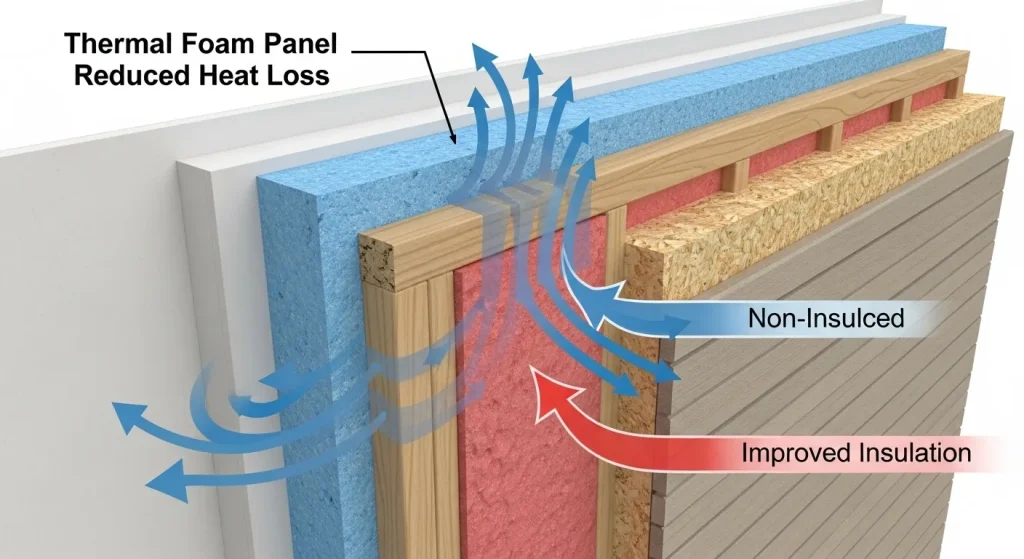

A thermal bridge is a path of least resistance for heat. In your wall, this is the wood stud. Heat will bypass your (R-13) insulation by traveling right through the (R-4) wood stud. This is a massive source of energy loss.

This is the most important concept in modern insulation. This is the "how" in the article's title.

Anecdote

The best way to "see" a thermal bridge is on a cold, frosty morning. Look at the outside of your house. You will often see a perfect "ghost" of your home's 2x4 studs on the frosty siding.

Why? The studs are warm because heat from your home is "bridging" right through them. That heat is melting the frost on the siding. That is a picture of your money escaping.

In a standard wall:

- Fiberglass Insulation: R-13

- Wood Stud: R-4.5

Heat is lazy. It will not fight its way through the R-13 fiberglass. It will take the R-4.5 "super-highway" through the wood stud. Up to 25% of your wall's heat loss can be from thermal bridging.

How Does a Foam Panel Stop Thermal Bridging?

A foam panel creates a "continuous insulation" layer.23 It is a seamless, unbroken blanket of insulation installed over the outside of the studs. This blanket covers the "thermal bridges." It isolates your home's entire frame from the outside temperature.

This is the single biggest "how" they improve insulation.

Instead of a wall of "R-13, R-4, R-13, R-4...", you now have a wall that is "R-13, R-4... plus a continuous R-5 (from the foam) over everything."

The foam panel "thermal break" stops the studs from acting as a highway for heat. This makes the entire wall perform better.

Where Are the Best Places to Use Thermal Foam Panels?

The best places for foam panels are basement interiors, exterior walls, and attics. In basements, they insulate and stop moisture.24 On exterior walls, they "wrap" the house. In attics, they seal and insulate the roof.

1. Basements (The #1 Use)

This is the perfect application for foam. For basements, XPS is the best choice. It is installed directly against the cold, damp concrete wall. It acts as an insulator, an air barrier, and a vapor barrier all in one product.

It stops the cold, damp concrete from touching the warm, interior air.25 This prevents condensation and mold. It is the foundation of a warm, dry, modern basement.

2. Exterior Wall Sheathing

This is common in new, high-efficiency construction. The foam boards are installed on the outside of the house, over the studs but under the siding.26 This "wraps" the entire home in a continuous foam blanket, stopping all thermal bridges.

3. Attics and Roofs

Polyiso is the top choice here.27 Its high R-value-per-inch is perfect for insulating a roof. You can install it on the underside of your roof deck. This creates a "conditioned" or "hot" attic, which is a very efficient way to build.

How Do Foam Panels Compare to Other Insulation?

Foam panels have a higher R-value per inch than fiberglass.28 They also stop air and vapor, which fiberglass does not. They are a "3-in-1" product.

Foam vs. Fiberglass Batts

Fiberglass batts (the pink, fluffy stuff) are cheap. But they are only an insulator. They do not stop air. They do not stop moisture. If fiberglass gets wet, its R-value drops to zero.

Rigid foam is a "closed-cell" board.29 It stops air (convection). It stops moisture (vapor). And its R-value is stable. It is a far higher-performance material.

Foam vs. Spray Foam

Spray foam (foamed-in-place) is also a fantastic, high-R-value, closed-cell insulator.30 It is excellent at sealing all the tiny air leaks. Its main downside is that it is a "pro-only" job and is very expensive.

Rigid foam panels offer a very similar "closed-cell" performance, but in a DIY-friendly, board-and-tape system.

Foam vs. PVC Panels: A Common Confusion

It is very important to understand this difference. Foam panels are for insulation. PVC panels are a finished wall covering. They are not competitors; they are partners.

- Foam: High R-value. Must be covered.

- PVC: Zero R-value. Is a durable, waterproof, finished surface.

Our foam vs. PVC wall panels guide explains this. The perfect basement wall is often foam insulation covered by a PVC panel system.

How Are Thermal Foam Panels Installed?

Foam panels are cut with a knife and attached with foam-safe glue or special fasteners. The most important step is to tape all the seams. This creates a continuous air and vapor barrier.

You can read our full how-to-install-foam-wall-panels guide, but here are the key pro-tips.

Pro-Tip: How to Cut Foam (The Right Way)

Do not use a power saw. This is my number one tip. It will create a "snow" of static-y foam dust that will cling to everything in your basement for the rest of time. It is a nightmare.

The "Score-and-Snap" Method:

- For boards up to 1-inch thick, this is the only way.

- Lay the board on a flat surface.

- Use a long straight-edge (like a 4-foot level) and a sharp utility knife.

- Score a deep, clean line.

- Snap the board over the edge of your table. It will break in a perfectly clean line.

For thicker boards (2-inch+), a simple hand saw is the next-best, low-mess option.

Why Is Taping the Seams So Important?

This is the step that separates the amateurs from the pros. A wall of foam panels is not an air barrier until you tape the seams.

- Use the Right Tape: Do not use duct tape. It will fail. You must use a high-quality "construction tape" or "seam tape" (like 3M) or a foil tape (for Polyiso).

- The Goal: You are turning 10 individual panels into one giant, monolithic, airtight sheet. This is what stops convection (air leaks).

Are Foam Panels Safe? (The Most Important Rule)

This is the most critical safety information you must know. Foam insulation is combustible.31 It burns fast and creates toxic smoke.

Because of this, building codes are non-negotiable:

All foam insulation inside a home must be covered by a 15-minute thermal barrier.

In 99% of cases, this means 1/2-inch drywall.

- You can never leave foam panels exposed in a living space.

- You can never leave foam panels exposed in a basement.

- You can not leave foam panels exposed in an attached garage.

- You can not just paint the foam.

This is not a suggestion. It is a life-safety and building code requirement. The only "exception" is for some specialized, fire-rated steel-faced panels used in foam wall panels for commercial use. For a home, you must cover it with drywall.

The Final Verdict: Are Thermal Foam Panels a Good Investment?

Yes. Thermal foam panels are one of the best, most effective investments you can make in your home's energy efficiency. They are a "3-in-1" product that solves the biggest problems in building science.

They do not just add R-value. They stop thermal bridging. They stop air leaks. They stop moisture.

They are the key to a modern, high-performance, and comfortable home. They lower your bills, make your rooms warmer, and prevent moisture problems. When installed correctly and safely, they are a one-time upgrade that pays you back for a lifetime.