Best Adhesives and Fasteners for Wall Cladding: Top Durable Cladding

The Definitive Guide to a Secure and Long-Lasting Installation

Improving the look of a building, wall cladding works as one of the important protective layers for buildings. When doing residential facades or commercial exteriors as well as interior paneling, the best adhesives and fasteners for wall cladding will influence both effectiveness and lifespan of the building. We will discuss some recommended adhesives and fasteners for various types of wall cladding materials. Select products that withstand extreme conditions, are compatible with the materials, require minimal effort in terms of installation methods, while still ensuring maximum efficiency for system performance and durability.

What Makes Adhesives and Fasteners Important in Wall Cladding?

Selecting adhesives together with fastening proposals is are vital part of wall cladding implementation. The wrong choice of glue or fastener will cause panels to part ways, resulting in excess moisture penetration, which causes unnecessary damage.

• Efficient wall cladding installation: Correct gluing, integrated with applicable fixing methods, ensures no loosening takes place during use.

• How long do these withstand weather exposure? When used with glues that do not allow water or solvent intrusion into their bodies, hinges, on how fasteners are utilized: The two together resolve the question of durable fixings.

• Systemically, none could defeat the given vertical load: An adhesive bond with mechanical bolts would provide enough stability, thereby preserving cladding system integrity.

Control of waterproofing for water ingress prevention is especially vital in exterior joints. Protective outer barriers must be waterproofed while excellent sealant application coupled with proper adhesives safeguards external moisture infiltration, maintaining critical joint construction seamless closure from water ingress.

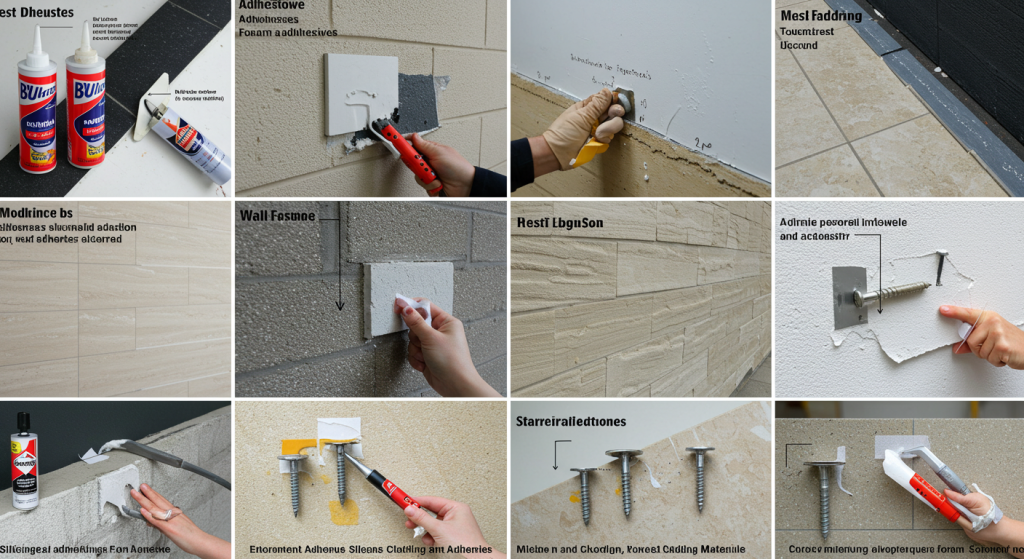

Examining Different Methods of Fixing Wall Cladding

The installation of wall cladding employs both mechanical and adhesive fasteners and a combination of both. Selection varies according to the cladding material, building design, and surrounding environment.

Mechanical Fasteners

Fastening mechanisms like bolts, clasps, or staples are described as mechanical fasteners. When structures face difficult challenges, these types of fastening techniques tend to be more reliable than adhesives:

- Stainless steel or galvanized screws stave off corrosion.

- Cladding clips and brackets are mostly concealed, which expands utility to rainscreen systems and aesthetic facades, making them ideal as complements.

- Nails (ring shank or collated): Useful for attaching wood siding and lightweight panels.

- Z girds and support rails: Used in rainscreen cladding to ventilate gaps.

Adhesives

Most of the contemporary construction industry has an alternative for almost every problem because modern innovations are continuously emerging. This means Advanced Grooving Wall Panel greater value and efficiency as applying adhesives becomes quicker, streamlined, or automated via minimal intervention. Some wall cladding adhesives include:

• Polyurethane adhesive (PUR): Strong, flexible bond and moisture resistant-ideal for rainy climates.

• Silicone sealants: Waterproof adhesives that seal effectively.

• Hybrid polymer adhesives: Silicone and polyurethane combined into one versatile form.

Best Adhesives for Wall Cladding: Technical Overview

The primary attributes that determine glue selection include the materials to be glued, external factors like weather conditions, temperature swings, winds precipitation.

Polyurethane Adhesive (PUR)

• Strength & Flexibility: PUR adhesives provide strong bonds while allowing flexibility capable of absorbing thermal expansion.

• Weather Resistance: Superior waterproofing and UV stability make them ideal for exterior applications, cladding.

• Common Applications: Wood cladding, fiber cement, and composite panels.

• Curing Time: Full cure takes 24-48 hours, but can be tack-free within minutes.

Epoxy Adhesive

Structural Strength: Provides the highest bond strength and chemical resistance.

Best For: Heavy stone cladding and metal panels that require a rigid bond are best fitted with these adhesives.

Moisture Resistance: Exceptional moisture resistance makes it useful in humid climates.

Limitations: Less flexible than other options; prone to cracking with substrate movement.

Silicone Sealants & Adhesives

Waterproof & Flexible: Silicone maintains adhesion through thermal cycling or movement.

Applications: Widely used as sealants, they are also applicable for lightweight panels like PVC.

UV Resistance: Excellent resistance to fading and degradation.

Hybrid Polymer Adhesives

All-Rounder: Mixture of strength with flexibility and ease of application.

Environmentally Friendly: Often solvent-free, low-VOC.

Usage: Cladding materials include metals, wood, and composites.

The Best Fasteners for Wall Cladding: Functions and Applications

Choosing a fastener affects the structure’s integrity and rust protection.

Stainless Steel Cladding Screws

• Corrosion Resistance: Useful in coastal areas or humid conditions.

• Strength: Heavy-duty design with high load-bearing capacity.

• Usage: Found on metal claddings, fiber cement panels, and composite systems.

Hidden Cladding Fasteners

• Clean facade–adds to the no visible heads advantage.

• Clips, brackets, concealed screws are examples of this category.

• Used in rainscreen systems and ACP.

Corrosion-Resistant Nails and Screws

• Combines galvanized steel, stainless steel, and coated fasteners.

• Galvanized unexposed surfaces protect against weathering.

Cladding Clips and Brackets

Support & Adjustment:

Allows thermal expansion as well as contraction.

Installation Ease:

Guarantees precision for large panels.

Z-Girts & Rails

Ventilation:

Holes behind the cladding allow drainage while providing airflow for drying.

Material-Specific Suggested Adhesives and Fasteners

Wood Cladding

Use box profile section rolls vented z-girts or rails along with ring shank nails or screws made out of stainless steel bound with polyurethane adhesive.

Indoor wooden panels can use PVA adhesives, but not outdoors.

Metal Cladding (Steel, Aluminum)

It is possible to attain strong bonds utilizing epoxy adhesives or hybrid polymers.

Fasteners Selection

Stone Cladding

• Mechanical anchors combined with epoxy adhesives are the most common methods of fastening and are preferred.

• Fasteners must be capable of enduring heavy loads and exposure to rain and humidity.

Fiber Cement Cladding

• Best mounting solution includes stainless steel screws and polyurethane adhesives.

Waterproof joints can be obtained through silicone sealants.

Composite Panels (ACP, HPL)

Use concealed clips for mounting along with hybrid polymer binders to boost structural rigidity.

To prevent panels from bowing, providing proper ventilation through rainscreen clips is essential.

Best Practices for the Application of Adhesives and Fasteners

Surface Preparation

Cleaning requires removing dust particles as well as grease or water from surfaces. This ensures substrate materials are clean, which may require some scrubbing.

Consistency in bonding strips increases when smeared surfaces are roughened.

Adhesive Application

Always observe set temperatures and curing periods for respective manufacturers; this information is standard among them. While dispensing adhesive, ensure even application by using appropriate tools like caulk guns or notched trowels for better control.

Fastener Installation

• In some cases, screw holes may be pre-drilled. However, project panels are prone to over-tightening, which can reduce their holding strength, requiring more careful handling.

• Use fasteners compatible with both the substrate and cladding material.

Eco-Friendly Advances in the Cladding Fixing Methods

The usage of eco-friendly polymers, MS polymer, and other solvent-free adhesives lowers environmental damage. Use of fasteners made out of recyclable materials also aids in achieving greener building envelopes.

Conclusion:

To accomplish an efficient weatherproof wall-cladding system, a combination of appropriate sealants, glue, and fasteners is critical in meeting the wall cladding project. Environmental conditions, design archetype, and functional intent should be guiding context for selection granularity for the chosen cladding material. HSCS Decor provides expert advice along with premium supplies that fulfill your wall-cladding needs. Weatherproof your cladding by reviewing our product offerings and installation services.