Foam Wall Panels and Insulation: Lightweight, Waterproof, and Energy Efficient

Foam wall panels & insulation describe a wide range of products, from thin, decorative "brick" stickers to thick, high-performance building boards. This is a point of great confusion for many homeowners. Are you buying a cosmetic fix or a high-efficiency thermal barrier?

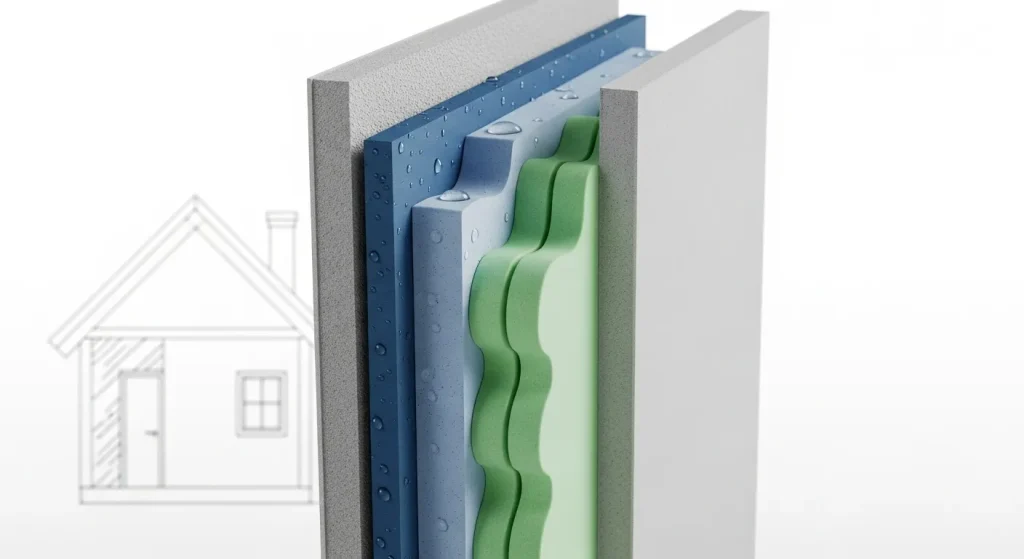

This guide clears up the confusion. We will explain the critical differences between the two main types of foam panels. First, the 3D decorative foam tiles that are lightweight and easy to install.1 Second, the rigid foam insulation boards that are waterproof, energy-efficient, and a core part of modern construction.

We will cover the specific types, the real-world benefits, the installation process, and the critical safety information you must know.

What Are Foam Wall Panels?

Foam wall panels are a broad category of building material. They range from thin, 3D decorative tiles for looks to thick, rigid insulation boards for energy savings. The decorative panels are a lightweight, cosmetic fix.3 The rigid boards are a structural, high-performance insulator.

Understanding this difference is the most important first step. One is for looks. The other is for performance. They are not the same product, and they do not solve the same problems.

Type 1: 3D Decorative Foam Wall Tiles

These are thin, soft, "peel-and-stick" squares or rectangles. They are made of a lightweight foam-wall-panel (like PE foam) and have an embossed design. The most common designs look like bricks, wood grain, or geometric patterns.

These panels are a fast, DIY-friendly cosmetic upgrade. You can cut them with scissors and stick them to a wall in an afternoon. Their main purpose is to cover an ugly, boring, or slightly damaged wall with a new texture.

Do Decorative 3D Foam Panels Provide Insulation?

No. Decorative foam tiles offer almost zero insulation. Their R-value is negligible. They are too thin, and their "open-cell" soft foam does not trap air well. They are a cosmetic product, not an energy-saving one. Do not buy them to heat your home.

I have seen many online listings for these "brick" stickers claiming they save on energy bills. This is just not true. A 1/4-inch soft foam sticker has less R-value than a piece of cardboard. They are for looks, and that is all.

Are Decorative Foam Panels Waterproof?

No. They are "water-resistant" at best. The plastic top surface will repel a splash of water, but the seams are not sealed. Water can (and will) get behind them. The soft foam backing can then absorb this water, creating a perfect, dark, damp place for mold to grow.

I would never install these in a "wet" area like a shower. They are for dry areas where you want a quick visual change.

What Is Rigid Foam Insulation? (The Real Foam Panel)

This is the high-performance, thermal foam wall panel used in construction. These are dense, 4x8-foot boards, 1/2-inch to 4-inches thick. They are made from dense, "closed-cell" polystyrene or polyisocyanurate. They provide very high R-value, create an air barrier, and manage moisture.

These are the real foam wall panels for insulation. They are a core product for making a home energy-efficient.

What Is R-Value?

R-value is a measure of thermal resistance.4 It is how well a material stops heat from passing through it. A higher R-value means better insulation.5 Rigid foam has a very high R-value per inch of thickness.6

This is the key metric. You are "buying" R-value when you buy insulation.

Type 1: Expanded Polystyrene (EPS)

EPS is a lightweight, "bead-board" foam.7 It is made of small white polystyrene beads that are fused together with heat and pressure.8 You would recognize this as the same material used in coffee cups or protective packaging.

It is the most affordable rigid foam. It offers a great R-value, typically R-4 per inch. It is versatile and is often used as a base for stucco or as a layer in structural insulated panels (SIPs). Its main drawback is that its "bead" structure can absorb water over time if not protected.9

Type 2: Extruded Polystyrene (XPS)

XPS is a dense, closed-cell foam. It is usually pink (Owens Corning) or blue (DuPont). It is made in a continuous "extruded" process. This creates a very consistent, closed-cell structure.

XPS has a high R-value of R-5 per inch. Its main benefit is its high resistance to moisture. The closed cells do not absorb water. This makes XPS the number one choice for insulating basement walls, foundation exteriors, and for any "below-grade" or damp environment.

Type 3: Polyisocyanurate (Polyiso)

Polyiso is a high-performance foam. It has the highest R-value, around R-6.5 per inch. It is a closed-cell foam that is almost always sold with a foil-facing on both sides.

This foil-facing is a huge benefit. It acts as a built-in radiant barrier. This means it reflects heat, which adds even more energy savings. Polyiso is a top choice for insulating roofs, attics, and exterior walls where you want the most R-value in the thinnest possible panel.

Quick Comparison: Rigid Foam Types

| Feature | EPS (Expanded) | XPS (Extruded) | Polyiso (Polyisocyanurate) |

| R-Value/Inch | ~ R-4 | ~ R-5 | ~ R-6.5 |

| Appearance | White "bead-board" | Pink or Blue boards | Yellow core, foil-faced |

| Moisture | Water-resistant | Water-resistant | Water-resistant (foil is a barrier) |

| CostNext | Low | Medium | High |

| Best For | Above-grade, roofs, budget jobs | Basements, below-grade | Roofs, thin-wall applications |

How Do Foam Panels Improve Energy Efficiency?

Foam panels stop heat loss in two main ways. First, their high R-value (from trapped gas in the closed cells) slows heat transfer. Second, they create a "continuous insulation" barrier.15 This stops heat from escaping through the cold wood studs.

This second point is the most important one.

What Is a "Thermal Bridge"?

In a normal wall, your wood studs (the 2x4s) are a "thermal bridge." Wood is a poor insulator. It has an R-value of about R-4.5 total, while the fiberglass between the studs is R-13.

Heat will always follow the path of least resistance. In winter, heat from your home "bridges" or escapes right through the studs. You can often see where studs are on a cold day; they are the coldest part of thewall.

A foam board "blanket" on the outside of the wall stops this. It creates a continuous, unbroken layer of insulation. It covers the studs. This "thermal break" is one of the biggest single improvements you can make to a wall's energy efficiency.

Are Foam Wall Boards Waterproof?

Closed-cell rigid foam, like XPS and Polyiso, is highly water-resistant. The panels will not absorb water. They do not rot, support mold growth, or disintegrate. This makes them a waterproof foam wall board and ideal for basements or as exterior sheathing.

This is a key difference from other materials. Fiberglass insulation, if it gets wet, will compress and lose all its R-value. Drywall, if it gets wet, will turn to mush and grow mold.

XPS is the true star here. You can install it directly against a concrete foundation wall. It acts as an insulator and a vapor barrier at the same time. This is why it is the standard for modern basement finishing.

Foam vs. PVC Wall Panels: What is the Difference?

The difference is function. Foam panels are for insulation. PVC panels are a finished wall covering. PVC is a thin, durable, waterproof skin. Foam is a thick, insulating core. They are not interchangeable.

A foam vs. PVC wall panel comparison is about what job you need done.

- PVC: Is for covering a wall in a bathroom, kitchen, or garage. It is 100% waterproof, durable, and a finished look. It has no R-value.

- FOAM: Is for insulating a wall. It has a very high R-value. It is not a finished look and must be covered.

Here is the pro-tip: You use them together. For a basement, the perfect wall system is to install XPS foam against the concrete, build a stud wall in front of it, and then cover that wall with PVC panels. You get insulation from the foam and a 100% waterproof, finished surface from the PVC.

Foam vs. Fiberglass Batt Insulation

Rigid foam is a dense board. Fiberglass is a "fluffy" batt.22 Foam has a higher R-value per inch. Foam also stops air and vapor.23 Fiberglass is cheaper but requires a separate vapor barrier and does not stop air leaks.

| Feature | Rigid Foam (XPS) | Fiberglass Batts |

| R-Value/Inch | R-5 | R-3.5 - R-4 |

| Air Barrier? | Yes | No |

| Vapor Barrier? | Yes (XPS/Polyiso) | No (Needs plastic) |

| Installation | DIY-friendly, no itch | Itchy, needs a mask |

| Cost | Higher | Lower |

For most projects, foam is a higher-performance material. It controls heat, air, and moisture in one product.

Where Are the Best Places to Use Rigid Foam

Rigid foam is best for basements, exterior walls, and attics. In basements, it insulates and stops moisture. On exterior walls, it creates a "thermal wrap." In attics, it seals and insulates the roof deck.

- Basement Walls: This is the #1 use. Install 1-2 inches of XPS or Polyiso directly against the concrete foundation. This stops moisture and insulates the cold wall.

- Exterior Walls (Sheathing): Install foam boards on the outside of your house, under the siding. This "wraps" your home in a foam blanket, stopping all thermal bridging.

- Attics: You can use foam boards to insulate the "roof deck" (the underside of your roof).25 This creates a "conditioned" attic, which is more efficient.

- Commercial Use: Foam wall panels for commercial use are common in cold storage, warehouses, and office buildings to meet high energy-efficiency codes.

How Do You Install Rigid Foam Panels?

Installing foam panels is a direct, DIY-friendly job. You can glue them to a flat wall (like concrete) with a special foam-safe adhesive. You can also fasten them with screws and special washers. The most important step is to tape all the seams.

Our full guide on how to install foam wall panels has more detail, but here is a simple overview.

A Simple Step-by-Step Installation Guide

- Prepare the Wall: The wall must be clean, dry, and flat. For a concrete wall, brush off any dust.

- Cut the Panels: This is the best part. It is easy.

- Pro-Tip: Do not use a big saw. For boards up to 1-inch thick, use the "score-and-snap" method. Use a utility knife and a long straight-edge (like a level). Score a deep line, then snap the board. It is a clean, fast, and dust-free cut. For thicker boards, a simple hand saw works perfectly.

- Attach the Panels:

- On Concrete: Use a "foam-safe" construction adhesive. It will say this on the tube. Regular adhesives can melt the foam. Apply it in an "S" pattern and press the board to the wall.

- On Wood Studs: You can use "cap-nails" or special screws with large plastic washers.

- Tape the Seams (The Critical Step): This is the most important step for an air/vapor barrier. You must tape every seam where two panels meet. Use a high-quality "construction tape" (like 3M) or foil tape (for Polyiso). This stops air from leaking through the cracks.

- Seal the Edges: Use a can of spray foam to seal the gaps at the top (ceiling) and bottom (floor) of the wall.

What Are the Downsides of Foam Insulation?

The main downsides are cost, environmental concerns, and fire risk. Foam is more expensive than fiberglass.26 It is a petroleum-based plastic. Most importantly, it is combustible and must be covered by a fire barrier.

Is Foam Insulation a Fire Hazard?

Yes. This is the most important safety rule. Foam insulation is combustible. Building codes are very clear: it must be covered by a 15-minute thermal barrier.28 This is usually 1/2-inch drywall.

You can never leave foam panels exposed in a living space, basement, or attached garage.

- A foam wall in a basement? It must be covered by drywall.

- A foam wall in a garage? It must be covered by drywall.

- This is not a suggestion. It is a non-negotiable building code and fire-safety requirement. The "decorative" foam panels are also plastic and have the same fire-safety concerns.

Is Foam Insulation Bad for the Environment?

This is a complex issue. Foam is a petroleum-based plastic, so it is not a "natural" product. The "blowing agents" used to make some old foams (like XPS) had high global warming potential (GWP).

The industry has improved. Newer foams use blowing agents with a much lower GWP.29 The argument for foam is that the energy it saves over the 50+ year life of a home far outweighs the environmental impact of its manufacturing.30

Are Foam Wall Panels the Right Choice for Your Project?

This depends on your goal.

- If your goal is a fast, cheap, cosmetic fix, then 3D decorative foam tiles are a lightweight foam-wall-panel option. Just do not expect them to insulate your home or stop water.

- If your goal is real energy savings, a warmer home, and moisture control, then rigid foam wall panels & insulation are one of the best investments you can make.

When used correctly (especially XPS in a basement) and installed safely (covered by drywall), rigid foam is a high-performance product. It is the key to a modern, comfortable, and energy-efficient home.