Lightweight Foam Wall Panels: A Complete Guide to Uses and Advantages

This guide provides a deep look at lightweight foam wall panels uses and advantages. These panels are one of the most misunderstood products in the design and renovation world. Some people picture the soft, peel-and-stick 3D brick patterns. Others picture the thick, rigid boards used to insulate a basement. They are both correct.

As an installer and designer, I have seen these panels solve critical problems. I have also seen them fail when used for the wrong job. "Foam panel" is not one single product. It is a family of materials.

This article is your expert guide. We will define the different types of foam panels. We will explore their powerful advantages, like insulation and water resistance. We will cover their real-world uses. Most important, we will cover their one critical weakness and the non-negotiable safety rules you must follow.

What Are Lightweight Foam Wall Panels?

Lightweight foam wall panels are a type of wall covering, not a structural support. They are made from polymer-based foams.1 Their primary purpose is to add insulation, manage moisture, or provide a fast, decorative 3D surface. They are a "skin" for your existing walls.

The single feature that defines them is their weight. They are made mostly of air. This makes them easy for one person to handle and install. It also means they do not add a heavy load to your building's structure.

To understand their uses, you must first learn the two main categories.

What Are the Main Types of Foam Panels?

The main types are flexible polyethylene (PE) foam panels used for decoration, and rigid polystyrene (XPS/EPS) or polyisocyanurate (ISO) boards used for insulation. These two groups have completely different uses.

These products are not interchangeable. Using a decorative panel for insulation will fail. Using an insulation panel as a final finish is often illegal.

Type 1: Polyethylene (PE) Foam Panels (The 3D Decorative Type)

These are the panels you see in many DIY videos. They are soft, flexible, and squishy to the touch.

- Composition: Closed-cell polyethylene foam.

- Look: They are almost always 3D-molded to look like brick, stone, or wood.

- Installation: They are "peel-and-stick." They have an adhesive backer.

- My Take: I call these "renter-friendly" panels. They are a fast, cheap, and temporary way to cover a bad wall. They also have a secondary benefit of being soft, which is great for a kid's playroom.2 They offer almost no R-value (insulation).

Type 2: Polystyrene Foam (EPS and XPS) Panels (The Rigid Insulators)

This is the most common type of "utility" foam. It is rigid and comes in large 4x8-foot sheets.

- EPS (Expanded Polystyrene): This is the white, "bead board" foam.3 It is made of many small beads pressed together. It is cheaper and has a lower R-value. It is water-resistant, but not fully waterproof.

- XPS (Extruded Polystyrene): This is the rigid foam, usually pink or blue. It is a "closed-cell" foam, meaning it is waterproof. It is denser and has a higher R-value than EPS.

- My Take: XPS is my go-to workhorse for basements. It is waterproof, strong, and a great insulator.

Type 3: Polyisocyanurate (Polyiso/ISO) Panels (The Premium Insulator)

This is a premium, high-performance foam board.

- Composition: A rigid foam core with a foil facing on both sides.

- Look: It is a yellow foam core with shiny silver (foil) faces.

- Key Feature: It has the highest R-value per inch of any common foam, around R-6.5.

- My Take: This is the top-shelf product for insulation. The foil facing also acts as a radiant barrier, which is a big plus.4 It is the most expensive of the rigid boards.

Foam Panel Comparison Table

| Feature | PE Foam (3D Decorative) | EPS (Bead Board) | XPS (Rigid Board) | Polyiso (Foil-Faced) |

| Primary Use | Decoration, Sound Dampening | Insulation (Budget) | Insulation, Waterproofing | Premium Insulation |

| Structure | Flexible, Soft | Rigid, Brittle | Rigid, Strong | Rigid, Strong |

| Waterproof? | Yes | No (Water-resistant) | Yes (Closed-Cell) | Yes (Closed-Cell) |

| R-Value (per inch) | ~R-1 (Poor) | ~R-3.8 (Good) | ~R-5 (Excellent) | ~R-6.5 (Best) |

| Installation | Peel-and-Stick | Adhesive / Fasteners | Adhesive / Fasteners | Adhesive / Fasteners |

What Are the Core Advantages of Foam Panels

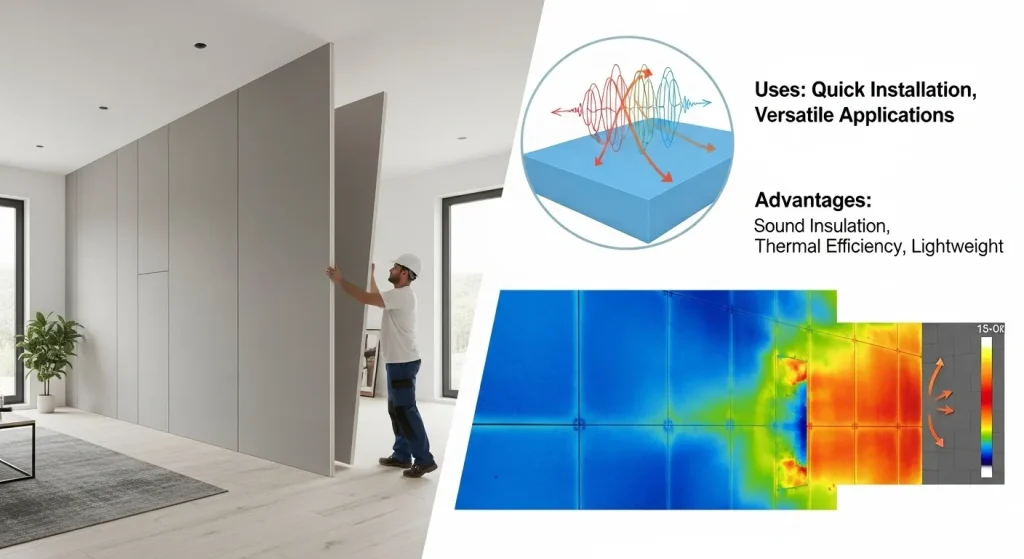

The main advantages of foam panels are their high R-value, light weight, and water resistance. They are also fast to install. The specific advantages depend on the type of foam you use.

Advantage 1: Excellent Thermal Insulation

Foam panels have a very high R-value per inch. R-value measures resistance to heat flow.5 A high R-value means the panel is very good at stopping heat transfer. This keeps your room warmer in winter and cooler in summer.

Rigid foam is the star here. A 2-inch thick XPS board gives you an R-10 insulation value.6 To get R-10 from fiberglass batts, you would need almost 3.5 inches of space. This makes foam a perfect choice for insulating walls where space is tight. You can learn more at our guide to foam wall panels insulation.

This is the main benefit of thermal foam wall panels. They pay for themselves over time in energy savings.7

Advantage 2: Are Foam Panels Waterproof?

Yes, closed-cell foam panels like XPS, PE, and Polyiso are 100% waterproof.8 They are non-porous. They cannot absorb moisture, swell, rot, or grow mold. This makes them a perfect material for high-humidity or below-grade (underground) areas.

- EPS (Bead Board): This is the exception. It is "open-cell." Water can get between the beads. It is water-resistant, but I do not use it for waterproof applications.

- XPS & PE Foam: These are "closed-cell."9 The foam bubbles are not connected. They are completely waterproof.

This is why they are the modern choice for basements. You can install a waterproof foam wall board directly against a concrete foundation. It acts as a vapor barrier and insulation in one step.

Advantage 3: How Easy Are They to Install?

Foam panels are one of the easiest wall-covering and insulation products to install.10 This saves a huge amount on labor costs.11

- Extremely Lightweight: This is the key. I can carry a 4x8-foot sheet of 2-inch XPS with one hand. A sheet of drywall is a heavy, two-person job.

- Easy to Cut: You do not need a saw. You can cut rigid foam with a simple utility knife.12 Score it, and it snaps clean. This means no dust.

- No Mess: Compare this to drywall, which requires days of mudding, taping, and sanding. Or cement board, which is heavy and creates a cloud of silica dust.

- 3D PE Panels: These are even easier. They are peel-and-stick. You cut them with scissors and press them on the wall.

This ease of use is detailed in our how-to-install-foam-wall-panels guide.

Advantage 4: Do They Offer Sound Dampening?

Yes, foam panels provide good sound dampening, but not soundproofing. This is an important distinction.

- Sound Dampening (Absorption): Foam, especially the soft PE foam, is good at absorbing sound.13 It stops echo (reverberation) inside a room. This makes a room feel quieter and calmer.

- Soundproofing (Blocking): Foam is lightweight.14 It is terrible at soundproofing. It will not stop your neighbor's music. Soundproofing requires mass (like thick drywall or concrete).15

I recommend 3D PE foam panels for playrooms. The soft, squishy foam is great at absorbing the high-frequency sounds of kids yelling. It makes the room feel less chaotic.

What Are the Disadvantages and Common Problems?

This is the most important part of this guide. As an installer, I must be clear about the trade-offs. Foam panels have two major weaknesses: low durability and fire risk.

Disadvantage 1: Low Impact Durability

Foam is soft. This is its biggest weakness.

- PE Foam (3D): You can press your thumbnail into it. It is not a durable surface.

- XPS/EPS: These rigid boards are stronger, but they will dent. A misplaced chair, a bicycle handlebar, or a bump from a vacuum cleaner will leave a permanent dent.

- You Cannot Hang Things From It: You cannot put a screw in a foam panel and hang a picture. The panel has no structural strength. You must use a long anchor or screw that goes through the foam and into the solid wall or stud behind it.

Disadvantage 2: FIRE SAFETY (The Critical Warning)

Foam is combustible. This is not a suggestion. It is a fact. All foam panels (PE, EPS, XPS, ISO) are made of plastic. They will melt and burn.

- Building Code Is Law: Because of this, building codes are very strict.16 You cannot leave rigid foam panels exposed in any living space.

- The Rule: All rigid foam must be covered by a 15-minute thermal barrier. The most common thermal barrier is 1/2-inch (12.7mm) drywall.

- My Warning: I have seen people install XPS foam on a garage wall and leave it exposed. This is a massive fire hazard. A fire will spread across that wall in seconds. You must cover it with drywall.

- Exception: The 3D PE peel-and-stick panels are so thin that they are often exempt, but you must check your local codes.

Disadvantage 3: UV and Heat Sensitivity

- Sunlight: Direct sunlight (UV rays) will degrade all foams. They will become brittle and start to crumble. They are for interior use or must be covered on the exterior.

- Heat: Foam has a low melting point. You cannot use it as a backsplash behind a stove. It will melt.

Where Are the Best Uses for Foam Panels?

The best uses for foam panels are in basements for insulation, in bathrooms as a waterproof tile backer, and as a fast, decorative skin for rentals.

Use 1: Basement Insulation (The #1 Application)

This is the perfect job for rigid XPS or Polyiso foam.

- Why it works: Basements are cold and damp.17 Rigid foam solves both problems. It is 100% waterproof, so it can go right against the cold concrete wall. It is a high-R-value insulator.

- Pro-Tip: My standard process for a high-quality basement is to glue 2-inch XPS foam board directly to the concrete foundation. I tape all the seams with house-wrap tape. This creates a perfect, continuous waterproof and insulated "blanket." Then, I build the 2x4 stud wall on the inside of the foam. This prevents "thermal bridging" and gives you the warmest, driest basement.

- Remember: You must cover this with drywall to meet fire codes.

Use 2: Bathroom and Shower Walls (As Tile Backer)

This is a modern, professional application. Products like Wedi Board or Kerdi-Board are not "foam panels"; they are foam tile backer boards. They have a high-density XPS foam core with a reinforced, waterproof coating.

- Why it works: They are 100% waterproof and ready for tile.18

- My Take: I use foam backer board for almost all my shower builds. It is a game-changer. A 4x8 sheet of cement board is a 100lb, two-person job that creates a toxic dust cloud. A 4x8 sheet of foam backer board weighs 15lbs. I can carry it with one hand, cut it with a utility knife, and it is waterproof the second it is up. It saves a full day of labor.

Use 3: 3D Decorative Accent Walls (The Quick Fix)

This is the main use for the 3D PE peel-and-stick panels.

- Why it works: They are cheap, fast, and require zero skill.19

- Who is it for?

- Renters: Cover a damaged or ugly wall without permanent changes.20

- Playrooms: The soft, squishy surface is safe for kids.

- Staging: A fast way to add a "brick" accent wall to sell a home.

- My Take: Be realistic. It looks good from 10 feet away. Up close, it looks like foam brick. It is a great budget solution, but it is not a premium finish.

Use 4: What About Commercial Use?

Yes, foam panels are a major component in commercial buildings.

- EIFS (Exterior Insulation and Finish Systems): Many modern commercial buildings are wrapped in rigid foam board. A synthetic stucco or other finish is then applied over it.

- Cold Storage: Walk-in freezers and cold-storage warehouses are built almost entirely from thick, insulated foam panels.

- Warehouse Insulation: Polyiso boards with a white foil facing are often left exposed on the ceilings and walls of warehouses (check commercial codes).

How Do Foam Panels Compare to Other Materials?

How do foam panels stack up against the competition? It depends on the job.

Foam Panels vs. Drywall

- Foam: Is a waterproof insulator. It has no structural strength and is a fire risk.

- Drywall: Is a fire-resistant, structural "skin." It has no R-value and is destroyed by water.

- Verdict: They are not competitors. They are partners. The best wall system is foam + drywall.

Foam Panels vs. Cement Board

- Foam Backer Board: Is light, clean, and waterproof.21 It is more expensive.

- Cement Board: Is heavy, dusty, and messy. It is water-durable, but not waterproof (it needs a membrane). It is cheaper.

- Verdict: For DIY and pro-use, foam backer board is a superior, modern product.22

Foam Panels vs. PVC Panels

This is a key comparison. Both are plastic, waterproof panels.

- Foam: Is soft and insulating.

- PVC: Is hard and durable.23

- Verdict: This is the foam vs pvc wall panels dilemma.

- Use 3D PE Foam if you want a soft, "squishy," sound-dampening surface (like a playroom).

- Use PVC Panels if you want a hard, durable, scratch-resistant, and pre-finished surface (like a public bathroom or mudroom).

Foam Panels vs. WPC/Wood Panels

- Foam: Is a utility insulation product.

- WPC/Wood: Are premium, decorative, and durable finish products.

- Verdict: They do not compete. You would install foam for insulation, cover it with drywall, and then install WPC or wood panels on top as the final decoration.

The Final Verdict: Are Lightweight Foam Panels a Good Choice?

Lightweight foam wall panels are an excellent utility product and a decent budget-decor product.

You should use rigid foam (XPS/ISO) if:

- Your #1 goal is insulation (high R-value).

- You are finishing a basement or a concrete wall.

- You are building a shower and want a modern, lightweight tile backer.

You should use 3D PE foam if:

- You are a renter or want a temporary, low-cost accent wall.

- You are designing a playroom and want a soft, sound-dampening surface.

Foam panels are not a durable, "forever" finish. They are a functional, high-performance tool. Use them for their strengths—insulation and water control—and always cover them with a fire-rated barrier.