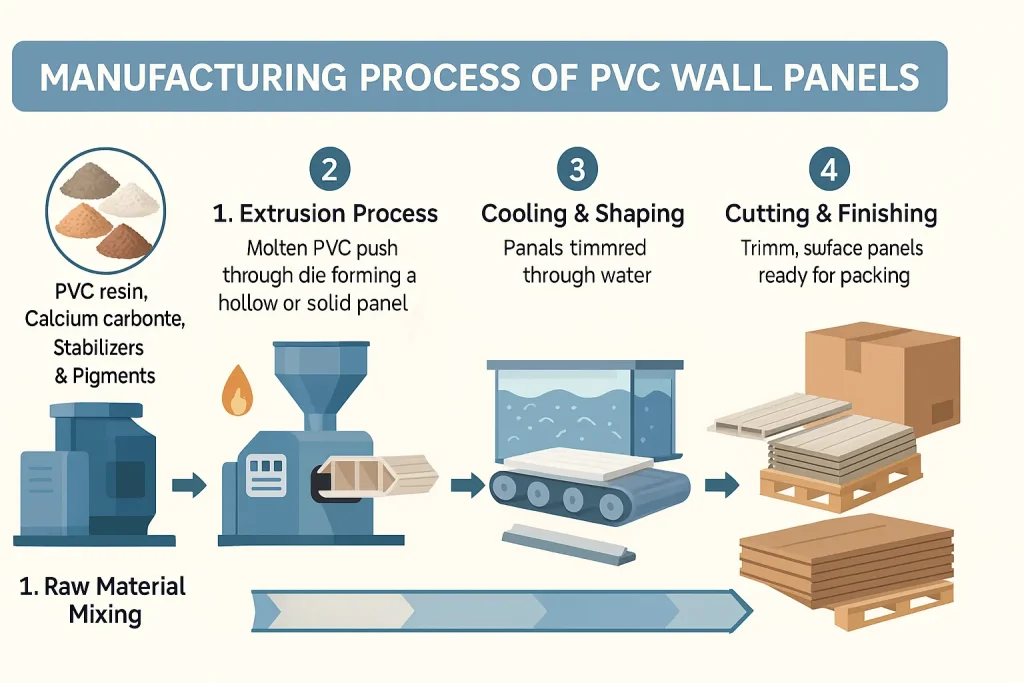

Manufacturing Process of PVC Wall Panels

The manufacturing process of PVC wall panels is a sophisticated operation that transforms raw chemical compounds into durable and beautiful building materials. Polyvinyl Chloride (PVC) panels are valued for their versatility, water resistance, and wide range of aesthetic options. This performance is not accidental. It is the direct result of a multi-stage, highly controlled production journey. From the initial creation of the base resin to the final application of a textured finish, each step is precisely engineered. This comprehensive guide provides an exhaustive, step-by-step exploration of this entire process. It offers a deep dive into the science and technology that turn simple raw materials into high-performance wall panels.

Phase 1: The Foundation - Synthesis of PVC Resin

Before a panel can be formed, its fundamental building block must be created. The journey of a PVC panel begins not in a panel factory, but in a chemical plant. This is where the base Polyvinyl Chloride resin is synthesized. This foundational stage involves transforming some of the planet's most abundant resources into a versatile and stable polymer. Understanding this initial chemical process is key to understanding the inherent properties of the final product.

Raw Material Sourcing: Salt and Fossil Fuels

The creation of PVC starts with two primary raw materials. The first is common salt, or sodium chloride. Through a process called electrolysis, an electric current is passed through a brine solution. This separates the salt into its constituent elements, producing chlorine gas. The second raw material is ethylene. Ethylene is a hydrocarbon that is derived from the thermal cracking of petroleum or natural gas. The responsible procurement of these base materials is a key aspect of the ethical sourcing of wall panel materials.

The Polymerization Process

The chlorine and ethylene are then combined in a chemical reaction to create a new substance called vinyl chloride monomer (VCM). This monomer is the essential building block of PVC. The next step is polymerization. The VCM is subjected to heat and pressure in a reactor vessel. This causes the individual monomer molecules to link together, forming incredibly long, repeating polymer chains. This chain is the Polyvinyl Chloride.

The Result: PVC Resin Powder

After the polymerization process is complete, the resulting PVC is dried. The final product of this stage is a fine, white, free-flowing powder. This is the raw PVC resin. In this form, it is a stable and inert material. It is the base ingredient that will be shipped to panel manufacturing plants. It is the starting point for countless products, from pipes and window frames to the decorative wall panels themselves.

Virgin vs. Recycled PVC Feedstock

It is important to note that the manufacturing process does not always have to start with virgin resin. PVC is a thermoplastic, which means it can be recycled. Old PVC products can be collected, sorted, and ground down into a powder or small pellets. This recycled material can then be used as a feedstock for the compounding phase. Using recycled PVC saves a significant amount of energy and reduces the consumption of fossil fuels.

Phase 2: Compounding - Creating the Perfect Recipe

Pure PVC resin on its own is not suitable for making a wall panel. It is a rigid but brittle material. To achieve the desired properties of durability, color, and processability, the raw resin must be blended with a carefully selected range of additives. This stage is called compounding. It is like being a chef, where a precise recipe of ingredients is mixed together to create a final compound with the perfect balance of properties. This is a critical step in the manufacturing process of PVC wall panels.

The Role of the PVC Compound

The goal of compounding is to create a homogenous mixture that is optimized for both the extrusion process and the final product's performance. Each additive in the recipe has a specific job to do. The exact formulation is a closely guarded secret of each manufacturer. It is what determines the quality, durability, and cost of the final panel. A detailed look at the material cost breakdown of WPC and PVC often relates back to the quality of these additives.

Essential Additives and Their Functions

The PVC compound is a complex mixture. Here are the most important additives and their roles.

- Stabilizers (Heat and Light): Pure PVC can degrade when exposed to high heat or UV light. Stabilizers are added to protect the polymer chains during the high-temperature extrusion process. They also provide long-term protection against UV radiation from the sun, preventing the panels from becoming brittle or discolored.

- Impact Modifiers: These are additives that increase the toughness of the PVC. They improve the panel's ability to withstand impacts without cracking or breaking. This is a crucial ingredient for a durable building material.

- Processing Aids: These are special polymers that help the molten PVC flow more smoothly and evenly through the extruder. They help to ensure a consistent, high-quality finish on the final panel.

- Fillers: Fillers, such as finely ground calcium carbonate, are often added to the compound. They can increase the rigidity and dimensional stability of the panel. They also play a role in managing the final cost of the product.

- Pigments: Pigments are used to give the PVC panel its base color. High-quality, stable pigments are chosen to ensure the color is consistent and long-lasting.

- Fire Retardants: For applications that require a specific fire safety rating, special fire-retardant additives are included. These chemicals are designed to disrupt the combustion process, making the panels self-extinguishing. The details of the fire rating for wall panel materials depend on these additives.

The High-Speed Mixing Process

The compounding itself takes place in a large, high-intensity industrial mixer. The PVC resin and all the powdered additives are precisely weighed and then fed into the mixer. The mixer uses high-speed rotating blades to create a vortex that blends the materials together perfectly. The friction from this process also generates heat, which begins to prepare the compound for the next stage. The result is a consistent, free-flowing powder ready for extrusion.

Phase 3: Extrusion - From Compound to Panel Profile

Extrusion is the heart of the manufacturing process of PVC wall panels. This is the stage where the powdered compound is transformed into a continuous, solid panel with the desired shape and profile. It is a highly automated and continuous process that can produce thousands of feet of paneling per hour. For a general overview of industrial production, see the Wikipedia page for Manufacturing.

The Anatomy of a Twin-Screw Extruder

The primary machine used is a twin-screw extruder. This is a long, heated barrel that contains two intermeshing screws that rotate. The compounded PVC powder is fed into the barrel at one end from a hopper. The rotating screws then carry the material down the length of the barrel.

Melting, Mixing, and Pressurizing

As the PVC compound travels along the extruder's barrel, it is subjected to intense heat and pressure. The external heaters on the barrel and the friction from the screws melt the compound into a thick, homogenous liquid, similar in consistency to dough. The screws are designed not only to convey the material but also to continue mixing it, ensuring a perfectly consistent melt. By the time the material reaches the end of the extruder, it is a fully plasticized and pressurized molten polymer.

The Role of the Die: Shaping the Panel

At the end of the extruder is a heavy steel tool called a die. The die is a precisely machined piece of metal that has an opening in the exact shape of the final panel's cross-section. The pressurized molten PVC is forced through this die. As it exits, it takes on the shape of the die. This is what creates features like the tongue-and-groove edges or the hollow-core structure of the panel.

Calibration and Cooling

The PVC profile that exits the die is still hot and malleable. It must be cooled and solidified in a controlled way to ensure it holds its shape. The profile is immediately pulled into a series of calibrators and cooling tanks. The calibrators use vacuum pressure to hold the profile against cooled metal surfaces that have the exact dimensions of the final panel. Water baths or chilled air are used to rapidly cool and solidify the PVC. This stage is critical for achieving tight dimensional tolerances.

Phase 4: Surface Finishing and Decoration

At this point, the product is a fully formed but plain, solid-color panel. The next phase is to apply the decorative finish that gives the panel its aesthetic appeal. This is where the magic of modern printing and finishing technology comes into play. These processes are what allow a simple PVC panel to convincingly replicate the look of natural wood or stone. These techniques are among the latest innovations in wall panel materials.

Printing and Lamination Technology

The most common method for creating realistic patterns is lamination. A thin decorative film is applied to the surface of the PVC panel. This film is printed with a high-resolution image using a technique called rotogravure printing. This allows for incredibly detailed and non-repeating patterns that capture every nuance of a natural material. The printed film is then permanently bonded to the PVC substrate using heat and a strong adhesive.

Hot Stamping and Heat Transfer

Another popular decoration method is hot stamping. In this process, the desired pattern is pre-printed on a carrier film. This film is then brought into contact with the PVC panel. A heated roller then presses the film against the panel. The heat and pressure cause the ink layer to be transferred from the carrier film directly onto the PVC surface.

Embossing for Realistic Texture

To create a truly convincing look, the panel must have a physical texture that matches the visual pattern. This is achieved through embossing. After the decorative layer is applied, the panel is passed through a set of large, textured rollers. One roller is engraved with the desired texture, such as a wood grain pattern. The roller is heated and presses the texture permanently into the panel's surface. This is what creates the tactile feel of real wood or stone.

Application of Protective Coatings

The final step in the finishing process is often the application of a protective topcoat. This is a clear, durable coating that is applied over the decorative layer. This coating is typically cured with ultraviolet (UV) light. It serves several important functions. It provides scratch and abrasion resistance.

Phase 5: Quality Control, Cutting, and Packaging

The final phase of the manufacturing process of PVC wall panels involves ensuring the product meets all quality standards before it is sent to the customer. This involves continuous monitoring, precise cutting, and careful packaging.

In-Line Quality Checks

Quality control is not just a final step; it is integrated throughout the entire process. Automated sensors monitor temperatures and pressures inside the extruder. Operators visually inspect the panel as it comes off the line. They check for any surface defects, color inconsistencies, or dimensional inaccuracies. This continuous monitoring ensures a consistent and high-quality output.

- Quality Control Checklist:

- Color Consistency: Is the color uniform across the panel and from one panel to the next?

- Dimensional Accuracy: Are the width, thickness, and straightness of the panel within the specified tolerances?

- Surface Finish: Is the printed pattern clear and free of defects? Is the texture correctly applied?

- Physical Integrity: Is the panel free of any cracks, chips, or other physical damage?

Precision Cutting to Length

The continuous panel that comes off the production line must be cut into standard, manageable lengths. This is done with a high-speed, automated saw that travels along with the moving panel to make a clean, precise cut without stopping the line.

Final Inspection and Packaging

After the panels are cut, they undergo a final visual inspection. They are then stacked and packaged. The packaging is designed to protect the panels from scratches and damage during shipping and handling. This ensures the product arrives at the job site in perfect condition. The quality of the final product is a direct reflection of the standards of the wall panel manufacturers in the region. For a general overview of materials, see the Wikipedia page for Material.

The manufacturing process of PVC wall panels is a remarkable journey. It transforms common raw materials like salt and natural gas into a sophisticated and high-performance building material. Through the precise science of compounding, the power of extrusion, and the artistry of modern printing and finishing, a simple polymer becomes a durable, beautiful, and versatile wall panel. Understanding this complex process provides a deeper appreciation for the quality and value that these modern materials bring to construction.