PVC vs WPC Wall Panels: Material, Durability, and Cost

Choosing the right wall panel can be confusing. You want a waterproof, low-maintenance solution, but the market is full of acronyms. The biggest choice you will face is PVC vs. WPC. Understanding the difference between PVC wall panels and WPC panels is the key to a successful project.

While they look similar online, they are built for entirely different purposes. One is a lightweight, budget-friendly "skin." The other is a heavy-duty, premium "board."

This guide will break down every comparison point. We will cover the core material, real-world durability, and true cost. By the end, you will know exactly which panel is right for your project.

What Is the Main Difference Between PVC and WPC?

The main difference is their core material. PVC panels are 100% plastic with a hollow, lightweight structure.1 WPC (Wood-Plastic Composite) panels have a solid, dense core made from a mix of plastic resins and wood fibers.2 This single change in composition affects their durability, weight, cost, and feel.

This is not just a technical detail. It is something you can feel with your hands.

I call this the "Thumb Test." If you take a standard, hollow-core PVC panel and press your thumb hard into its side, you can often feel the thin plastic wall flex or even collapse.

At-a-Glance Comparison: PVC vs. WPC

This table summarizes the most important differences. Use it for a quick reference.

| Feature | PVC Wall Panel | WPC Wall Panel |

| Core Material | 100% Plastic (PVC) | Wood-Plastic Composite |

| Core Structure | Hollow-Core (Fluted) | Solid-Core (Dense) |

| Feel & Weight | Very lightweight, flexible | Heavy, rigid, solid |

| Durability | Low. Prone to dents, punctures. | High. Resists impacts, dents. |

| Cost | Low (Budget-friendly) | Medium to High (Premium) |

| Waterproof? | Yes (100%) | Yes (100%) |

| Acoustic Insulation | Poor | Good |

| Thermal Insulation | Poor | Good |

| Installation | Very easy (light, cuts with knife) | Harder (heavy, needs saw) |

| Best For... | Ceilings, low-traffic bathrooms, budget flips | Feature walls, high-traffic areas, commercial |

What Is a PVC Wall Panel?

A PVC wall panel is a lightweight, hollow-core wall covering made from 100% Polyvinyl Chloride plastic.4 It is a completely waterproof, budget-friendly, and easy-to-install alternative to traditional materials like ceramic tile.

The key feature is its hollow structure. Inside, it has a series of "flutes" or rectangular tubes. This design uses the least amount of material possible. This is what makes the panel so light and affordable.

Because it is all plastic, it is a perfect solution for wet areas. It is also very easy to clean. It is a "utility-first" product. Its main jobs are to be waterproof and cheap. You can learn more in our full guide, PVC Wall Panels Explained.

What Is a WPC Wall Panel?

A WPC wall panel is a high-density, solid-core panel.5 It is made from a "Wood-Plastic Composite." This material is a mix of recycled wood fibers (like sawdust or wood flour) and plastic resins (like PVC or PE).6

These ingredients are heated and "extruded" into a solid board. The wood fibers give the panel its rigidity, density, and solid feel. The plastic encases all the wood, making the entire board 100% waterproof and rot-proof.

WPC was invented to create a panel that has the premium feel and strength of real wood, but without any of wood's drawbacks (like water damage, pests, or warping). It is a "premium-first" product.

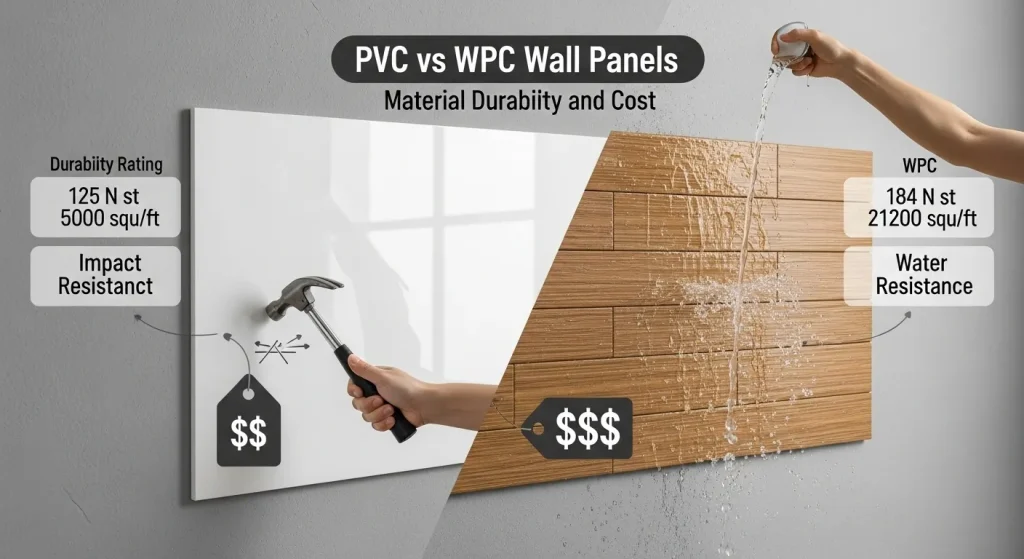

Durability Showdown: Which Panel Is Stronger?

WPC is far stronger and more durable than PVC. The solid composite core of WPC resists dents, scratches, and impacts. The hollow, thin-walled core of PVC can be easily punctured or dented, sometimes with minimal force.

This is the most important, practical difference between the two.

The PVC Durability Problem

I have seen this fail in the real world. A client (a friend of mine, to be clear) insisted on using low-cost, regular PVC panels to line his garage wall. He loved how cheap and easy it was.

Three weeks later, his son put his bicycle away. The handlebar lightly bumped the wall. The hollow PVC panel was not dented; it was punctured. There was a clean, half-inch hole right through it.

Regular PVC is not designed for impact. It is a skin. It is fine for a ceiling or a low-traffic shower wall, but it is not a "tough" material.

The WPC Durability Solution

WPC is built to be tough.8 The solid-core, 1/2-inch or 5/8-inch thick board is more like a piece of composite decking. It is designed to take a hit.

This is the panel you use for:

- Mudrooms: Where kids throw backpacks.

- Hallways: Where furniture gets bumped.

- Commercial Spaces: Restaurants, offices, and garages.

- Home Gyms: Where weights might hit the wall.

WPC is a "one-and-done" installation. You put it up, and you do not have to worry about it. The durability justifies the cost.

Waterproofing: Is There Any Difference?

No. Both PVC and WPC wall panels are 100% waterproof. The core materials (plastic and plastic-encased wood) do not absorb water. This makes both excellent choices for bathrooms, basements, and laundry rooms.

This is the one area where they are completely equal. Their ability to stop water is their main shared benefit over materials like drywall, MDF, or even tile (which has porous grout).

- PVC: It is a sheet of solid plastic. Water cannot get in.

- WPC: The wood fibers are completely saturated and sealed in plastic resin. Water cannot reach the wood.

If your only goal is waterproofing, and not durability, then both materials are a perfect choice.

Cost Comparison: Is WPC Worth the Extra Money?

WPC panels cost significantly more than PVC panels.9 You can expect a WPC panel to be anywhere from 50% to 150% more expensive. PVC is the clear budget choice. WPC is a premium upgrade where you are paying for durability, a solid feel, and better aesthetics.10

Let's break down the "value" of each.

- PVC (The Budget Option): This is the king of low-cost renovation.11 It is cheap to buy, cheap to ship (because it's light), and cheap to install (a fast DIY job). It is perfect for rental properties, flips, or a quick, clean update on a tight budget.

- WPC (The Premium Investment): This panel is an investment.12 You are paying more for the material upfront. You are paying for a panel that will not need to_ be replaced. The cost to repair or replace one damaged PVC panel in a high-traffic area would completely erase the initial savings.

So, is WPC worth it? Yes, but only in the right location. It is worth it for a media wall, a mudroom, or a garage. It is probably not worth it for a guest room ceiling.

Aesthetics and Feel: Which Panel Looks Better?

WPC generally looks and feels more premium than PVC.13 Its solid, heavy nature feels like real wood. Modern PVC printing is very good, but the panels can look "plasticky" and feel hollow when tapped.14

This is what I call the "Tap Test."

- PVC: When you tap a PVC panel with your knuckle, you hear a high-pitched, hollow, "tock-tock" sound. It sounds thin, like plastic.

- WPC: When you tap a WPC panel, you hear a low-pitched, solid "thud." It sounds like tapping on a solid wood door.

This acoustic feedback translates directly to a feeling of quality.

In terms of visuals, high-definition printing has made both look amazing. You can get realistic marble, concrete, and wood-grain finishes on both. WPC, however, is often used for 3D or "fluted" panels. Its rigid, solid structure can be milled and shaped in ways that hollow PVC cannot, giving it more architectural and high-design options.

You can learn more about the common looks of PVC in our what are PVC wall panels guide.

Insulation Properties (Sound and Heat)

WPC offers good acoustic and thermal insulation due to its dense, solid core.16 PVC offers almost no insulation. The hollow-core structure of PVC does very little to stop the transfer of sound or heat.

This is a huge, often-overlooked benefit of WPC.

- Acoustic (Sound) Insulation: The dense, wood-filled core of WPC absorbs sound waves.17 It makes a room quieter. This is a fantastic bonus for a home office, a home theater, or a bedroom. It helps deaden echos and block noise. PVC's hollow core can sometimes even amplify sound, like a drum.

- Thermal (Heat) Insulation: The solid WPC board adds a small but real R-value to your wall.18 It helps create a thermal break. The hollow air-filled chamber of a PVC panel provides almost no thermal benefit.

If you are finishing a cold basement, a WPC panel will make the wall feel warmer to the touch than a PVC panel will.

Sustainability: Which Is More Eco-Friendly?

WPC is generally considered more sustainable than standard PVC.19 The core of a WPC panel is made from recycled wood fibers (a waste product and a renewable resource) and recycled plastics.20 Standard PVC is often made from 100% virgin plastic, which is petroleum-based.

This is a complex topic, and you can find "green" and "non-green" versions of both.

- WPC: Starts from a sustainable base.21 It is designed to turn "waste" (sawdust and old plastic bottles) into a durable, long-lasting product.

- PVC: Is petroleum-based.22 It is not "green" by nature.

A durable product that lasts 30+ years (like WPC) is, by its nature, a sustainable choice because it reduces waste.23 It does not need to be replaced. You can, however, find sustainable PVC wall paneling options that include recycled content. This is a positive trend, but WPC's entire concept is rooted in recycling.

Installation: Is One Easier to Install?

PVC is slightly easier to install because it is so lightweight. It can be cut with a simple utility knife. WPC is heavy and requires a saw for every cut, making the installation more labor-intensive, messier, and slower.

This is a big deal for a DIY-er.

- Installing PVC (The DIY Dream):

- Weight: One person can easily handle a 10-foot panel.

- Cutting: You can use the "score-and-snap" method. Use a utility knife to score a line, and it snaps cleanly.

- Mess: There is no sawdust. It is a clean, quiet job.

- Installing WPC (The Pro Install):

- Weight: The panels are heavy. You may need two people to lift them.

- Cutting: You must use a saw. A miter saw, circular saw, or jigsaw is required.

- Mess: It creates a lot of fine composite/wood sawdust.

Both panels use a tongue-and-groove system. Both can be installed with construction adhesive.25 The process is the same, but the labor is very different.

The Final Verdict: When Should You Choose PVC?

You should choose PVC panels when your top priorities are budget and light weight. It is the perfect choice for ceilings, low-traffic residential bathrooms, and laundry rooms where durability is not a major concern.

Use PVC for:

- Ceilings (its light weight is a huge advantage here)

- Quick, low-cost bathroom or shower updates

- Rental property renovations

- Laundry rooms and utility closets

When Should You Choose WPC?

You should choose WPC panels when your top priorities are durability, a premium feel, and acoustic insulation. It is the clear winner for feature walls, high-traffic hallways, commercial spaces, and home theaters.

Use WPC for:

- Living room "media walls" or feature walls

- Mudrooms, entryways, and hallways

- Home offices and home theaters (for sound dampening)

- Garages and workshops

- High-end basements

- Any commercial or retail space