Stone Effect vs WPC Wall Panels: A Complete Cost Comparison

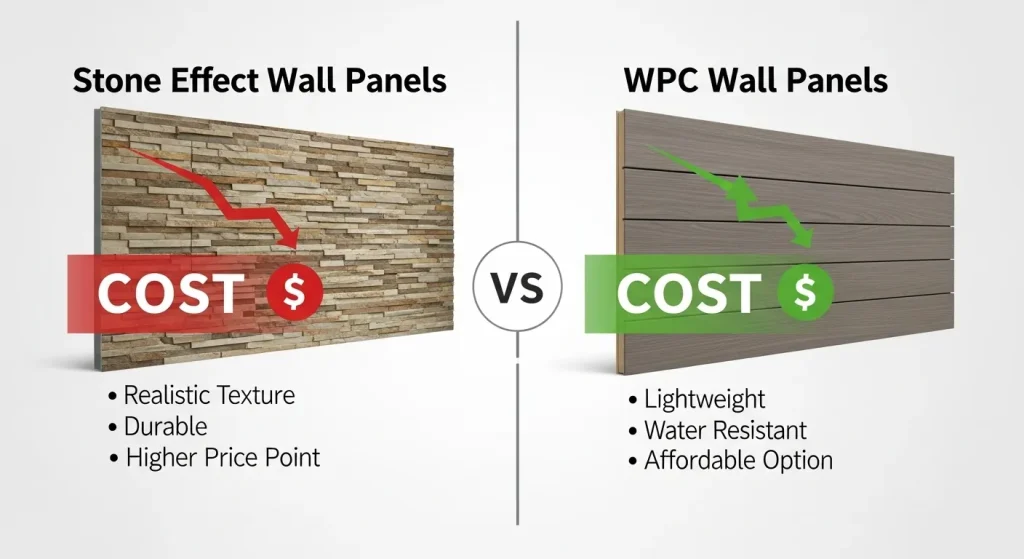

A cost comparison of stone effect vs WPC wall panels is one of the most common decision points for homeowners and builders. Choosing an exterior or interior cladding is a major investment. It defines your property's look and impacts your long-term maintenance load. Both stone effect and WPC (Wood-Plastic Composite) are popular for a reason. They both offer a high-end look without the extreme cost and difficulty of traditional materials.

But when they go head-to-head, which one truly offers the best value? The answer is not simple. The upfront price tag on the shelf is only one part of the story. I’ve seen clients save 20% on materials only to spend 40% more on a difficult installation.

This guide will break down every financial aspect. We will compare the upfront material costs, the hidden installation and labor costs, and the true long-term cost of ownership.

What is Stone Effect Wall Cladding?

Stone effect wall cladding is a lightweight, manufactured panel designed to perfectly mimic the look and texture of real natural stone. It is typically made from high-density polyurethane or a concrete-based composite. This material answers the question, "What is stone effect wall cladding?" It's a veneer.

These panels solve the two biggest problems of natural stone: weight and cost. Because they are light, you can install them on almost any wall without adding extra structural support. This makes them perfect for remodels. The best panels are cast from molds of real rock, making them look incredibly realistic. They are a popular choice in the wider world of stone & decorative cladding.

What is WPC (Wood-Plastic Composite) Wall Cladding?

WPC wall cladding is an engineered material made from a mix of recycled wood fibers and recycled plastics. It is designed to provide the warm, natural look of wood. But it does so without the constant maintenance like staining, sealing, or painting.

WPC panels are durable, water-resistant, and will not rot, warp, or splinter. This makes them a very popular, low-maintenance alternative to traditional timber. They come in many forms, from flat panels to modern fluted or slatted designs. WPC is a key part of modern architectural wall cladding trends due to its clean lines and sustainability.

The Big Question: Which is Cheaper Upfront?

Generally, WPC wall panels have a lower upfront material cost per square foot than high-quality stone effect panels. However, budget-grade stone effect panels can be competitive. Premium "capped" WPC panels with complex profiles can sometimes be more expensive than mid-range stone effect.

This is the most common question, but the answer is always "it depends." I've quoted projects where a client was set on a stacked stone effect, but their budget was tight. We switched to a standard flat WPC panel in a nice wood tone. This saved them about 20% on materials alone.

Conversely, I had another client who wanted a very specific, premium fluted WPC panel for an interior wall. In that case, a mid-range polyurethane stone effect panel was actually the cheaper option. The "sticker price" is just the beginning of your cost calculation.

Quick Cost Comparison: Material Only

| Cladding Type | Typical Price Range (per sq. ft.) | Notes |

| Stone Effect (Polyurethane) | Moderate to High | Price depends on panel thickness and realism. |

| Stone Effect (Concrete-Based) | Moderate | Heavier, but often a bit cheaper than poly. |

| WPC (Uncapped, Hollow) | Low to Moderate | Best for interiors; lower cost. |

| WPC (Capped, Solid Core) | Moderate to High | Premium product; best for exteriors. |

What Factors Determine the Cost of Stone Effect Panels?

The price of stone effect panels can vary wildly from one product to the next. The main cost drivers are the material used (polyurethane vs. concrete), the realism of the mold, the brand, and whether the panel is rated for exterior use.

Polyurethane vs. Concrete-Based?

- High-Density Polyurethane (HDP): These panels are extremely lightweight and often have the most realistic textures. The manufacturing process allows for deep, detailed molds. They are easy to cut and install. This advanced manufacturing and light weight can sometimes put them at a higher price point.

- Concrete-Based (Veneer): This is a "manufactured stone veneer." It's made from Portland cement, aggregates, and pigments. It feels more like real stone because it is a form of concrete. It's much heavier than polyurethane but often a bit cheaper. Its weight, however, adds to installation costs.

How Does the Mold Quality Affect Price?

This is a huge factor. Cheaper stone effect panels use the same few molds over and over. This creates a very obvious, repeating pattern on the wall.

Premium panels are cast from a huge variety of real stones. This means there are fewer repeats, and the final look is much more natural. This is a classic case of getting what you pay for. Better realism costs more.

Are Exterior Panels More Expensive?

Yes. Panels rated for exterior use cost more than "interior-only" versions. Exterior panels have special UV inhibitors blended into the material and finish. This prevents the sun from fading the colors over time. They are also built to withstand freeze-thaw cycles and extreme weather.

What Factors Determine the Cost of WPC Panels?

The WPC market is just as varied. The biggest cost factor is "capped" vs. "uncapped." The panel's profile (like fluted or slat) and its core structure also heavily influence the final price per square foot.

Capped vs. Uncapped WPC: Why Capped Costs More?

This is the most important difference in WPC.

- Uncapped WPC: This is the "first generation" of composite. The material is a homogenous mix of wood and plastic. It is less expensive but porous. This means it can be prone to staining, fading, and mildew, especially in damp or sunny areas. It's best suited for low-traffic interior use.

- Capped WPC: This is the modern standard. The WPC "core" is wrapped in a protective outer shell, usually made of a durable polymer. This "cap" makes the panel highly resistant to stains, fading, and scratches. It is the only type you should consider for exterior use. This extra layer adds to the manufacturing cost.

Solid Core vs. Hollow Core?

WPC panels come in two main structures.

- Hollow Core: These panels are lighter and use less material, making them cheaper. They are perfectly fine for most residential wall applications. The hollow channels can even provide some minor insulating properties.

- Solid Core: These are heavier, stronger, and feel more substantial. They are often used for commercial projects or in high-impact areas. They are more expensive due to the extra material.

How Do Panel Profiles Change the Price?

A simple, flat WPC panel that mimics traditional siding is the cheapest. The modern trend of fluted or slatted panels requires a much more complex manufacturing process. These intricate profiles use more material and are considered a premium design feature, which increases their cost.

Installation Costs: Which is Cheaper to Install?

WPC is almost always cheaper and faster to install than stone effect panels. WPC typically uses a simple clip-and-screw system. Stone effect often requires mortar, backer board, and more skilled labor, similar to tile work. This dramatically increases labor costs.

This is where the true cost comparison happens. The material price is only half the bill. The labor to install it is the other half.

DIY-Friendliness: Can I Install These Myself?

- WPC: This is very DIY-friendly. If you can use a level, a drill, and a saw, you can install WPC. Panels are designed to be interlocking. They attach to the wall (or to battens) with a hidden clip system. It's a clean, dry installation process. This means you can save 100% on labor costs.

- Stone Effect: This is less DIY-friendly.

- Lightweight Polyurethane panels can be a DIY job. They are often installed with construction adhesive and screws. It's manageable.

- Heavier Concrete-Based panels are not a good DIY job. They must be installed with mortar over a metal lath and scratch coat system, just like real stone. This is a wet, messy, and skilled job. I've seen more DIY failures here than anywhere else. People get the mortar mix wrong, and panels start popping off the wall a year later.

Professional Labor Costs: What Should I Expect?

- WPC: You can hire a general carpenter or a siding installer. The job is fast and straightforward. A crew can often clad an entire feature wall in a single day. Faster job = fewer labor hours = lower cost.

- Stone Effect: You need a skilled mason or a tile setter, especially for the concrete-based-panels. Their hourly rates are typically higher than a general carpenter's. The process is also much slower. The mortar application, setting each panel, and (if needed) grouting takes time.

What About Substrate Preparation Costs?

- WPC: WPC is often installed on battens (thin strips of wood or metal). This is a huge advantage. It means the panels can go over a slightly uneven or ugly wall. The battens create a flat, level surface. This system also creates a "rainscreen" air gap, which is great for exterior wall health.

- Stone Effect: This requires a perfectly clean and flat surface. For exterior use, you must install a water-resistant barrier (WRB) and then metal lath. You then apply a "scratch coat" of mortar to the lath. This all has to be done before you can even think about sticking the first panel. This adds significant material and labor costs.

Installation Cost at a Glance

| Factor | Stone Effect Panels | WPC Panels |

| DIY-Friendly? | Partially (Poly only). Concrete-based is a "No." | Yes, very. |

| Professional Needed? | Mason or Tile Setter (Higher Skill) | Carpenter or Siding Installer |

| Install Speed? | Slow (Mortar, setting time) | Fast (Clip system) |

| Substrate Prep? | Complex (Lath, scratch coat for exteriors) | Simple (Battens or direct to wall) |

| Mess? | High (Mortar, dust) | Low (Sawdust) |

| Winner: | WPC (By a large margin) |

What is the True Long-Term Cost of Ownership?

Stone effect panels often have a lower long-term cost of ownership. They are extremely durable and require almost no maintenance. WPC is also low-maintenance, but cheaper, uncapped versions can fade or stain over 10-15 years, potentially requiring replacement sooner.

This is the final piece of the financial puzzle. A product that costs 20% more but lasts twice as long is the cheaper option.

Lifespan and Durability: Which Lasts Longer?

- Stone Effect: High-quality stone effect, whether polyurethane or concrete, is incredibly durable. It is inert. It will not rot, be eaten by pests, or warp. The color is often mixed into the material itself. A good panel will look almost the same in 30 years as the day it was installed. We're talking a 30-50+ year lifespan. This is one of the key stone effect wall cladding benefits.

- WPC: A capped WPC panel has a very good lifespan, often warrantied for 20-25 years. The protective cap stops UV rays and prevents stains. An uncapped WPC panel is a different story. It can fade noticeably in direct sun. It's also more porous, so a spilled glass of wine or a grease splatter could leave a permanent mark.

Maintenance: What Cleaning is Required?

- Stone Effect: Almost zero. You can rinse it with a garden hose if it gets dusty. The textured surface hides dirt well. There is no sealing, painting, or staining required.

- WPC: Very low. You should wash it with mild soap and water every year or so. This prevents any surface mold or mildew from building up, especially in shady, damp areas.

Repairability: What if One Panel is Damaged?

- WPC: This is a clear win for WPC. Because of the clip system, you can (carefully) remove the panels from the top down to the damaged one. You swap in a new panel and reinstall the old ones. It's a straightforward fix.

- Stone Effect: This is very difficult. If a panel is mortared to the wall, you have to chisel it out. This risks damaging the surrounding panels. Then you have to mortar a new one in place. Trying to match the mortar color and the panel's "lot" (color batch) can be a nightmare.

Insulation (R-Value): Can They Save Me Money?

- Stone Effect: High-density polyurethane panels have a decent inherent R-value. This added insulation can lead to small but real energy savings over the life of the building. Concrete-based panels offer "thermal mass" but less R-value.

- WPC: The panel itself has minimal R-value. The real energy benefit comes from the installation method. The air gap created by installing on battens acts as a thermal break. This air gap stops heat transfer, improving your home's overall energy efficiency.

Final Verdict: A Head-to-Head Cost Comparison

| Feature | Stone Effect Panels | WPC Panels | Winner |

| Upfront Material Cost | Moderate to High | Low to Moderate | WPC |

| Installation Cost | High (Often needs a pro) | Low (DIY-friendly) | WPC |

| Installation Speed | Slow | Fast | WPC |

| Lifespan | Very High (30-50+ years) | Good (20-25+ years for capped) | Stone Effect |

| Maintenance | Almost Zero | Very Low | Stone Effect |

| Repairability | Difficult | Easy | WPC |

| Insulation (R-Value) | Good (Polyurethane) | Good (via air gap) | Tie |

| Aesthetic | Rustic, Natural, Textured | Modern, Clean, Wood-Look | (Subjective) |