What Are WPC Wall Panels and How Do They Work?

Understanding what are WPC wall panels and how do they work is essential for anyone considering a modern wall finish. These panels are engineered products that add style and durability to interior and exterior spaces. You have likely seen them creating striking feature walls in homes, hotels, or offices. They offer a simple way to get a high-end look.

This guide explains everything about WPC wall panels. We will break down what WPC stands for. We will look at the materials used to make them. This article answers the core questions homeowners and designers have about this popular building material.

Having worked with these panels on numerous projects, I have seen their practical benefits firsthand. They solve many common issues found with traditional materials like drywall or real wood. This article shares that practical knowledge.

What Is a WPC Wall Panel?

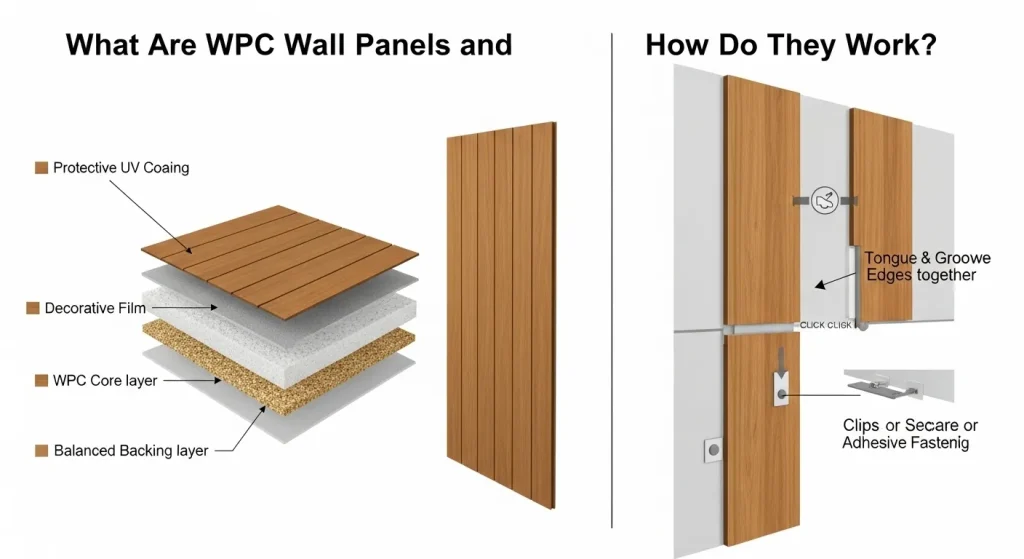

A WPC wall panel is a type of wall covering made from a Wood-Plastic Composite. This material blends fine wood fibers with plastic polymers. This combination creates a product with the natural appearance of wood and the resilience of plastic. Panels are designed to be durable, low-maintenance, and resistant to moisture.

These panels are more than just a decorative sheet. They are an engineered system. Most feature interlocking edges, like a tongue and groove. This design allows them to fit together seamlessly. This creates a clean finish and hides the installation screws. They are used to quickly transform plain walls, cover damage, or add a modern architectural element to a room. Our WPC wall panels guide offers a full introduction.

How Is WPC Material Actually Made?

WPC material is made by thoroughly mixing ground wood fibers with melted plastic. These two main ingredients are combined with other special additives. The additives help bond the wood and plastic. They also add color and protect against sun damage. This hot mixture is then pushed through a mold in a process called extrusion.

The extrusion process is what forms the panel's specific shape. This could be a flat profile or a popular fluted (slatted) design. As the long, continuous piece comes out of the mold, it is cooled with water or air. This hardens the material. After cooling, the panels are cut to their final lengths. Some premium panels receive a protective outer layer, called a "cap," in a separate co-extrusion step for added scratch resistance.

What Is the "Wood" Part of the Composite?

The "wood" part is typically recycled wood flour, sawdust, or fine wood fibers. This is a key component. It gives the WPC panel its rigidity and strength. Without the wood fibers, the panel would feel like a hollow, flimsy piece of plastic. The wood content provides the panel's body. It also contributes to the natural, textured feel that mimics real wood.

What Is the "Plastic" Part of the Composite?

The "plastic" part is a polymer, such as polyethylene, polypropylene, or PVC. This plastic is the binding agent. It melts during manufacturing and encapsulates all the tiny wood fibers. This process is what makes the final panel waterproof. The plastic creates a shield. It stops moisture from ever reaching the wood fibers, preventing rot, swelling, and warping.

What Is the Role of Additives?

Additives are the non-wood, non-plastic ingredients that give the panel its final properties. These small-quantity materials are critical for performance. They are mixed in with the wood and plastic before the extrusion process.

Here are the most common additives and their functions:

- Colorants: These are pigments that give the panel its base color.

- UV Stabilizers: These are essential for outdoor-rated panels. They protect the material from the sun's rays, which prevents fading and brittleness.

- Binding Agents: These chemicals ensure the wood fibers (which like water) bond permanently with the plastic (which repels water).

- Lubricants: These help the thick WPC mixture flow smoothly through the extruder's mold.

How Do WPC Wall Panels "Work" on a Wall?

WPC wall panels "work" by creating a durable, decorative, and protective skin over an existing flat surface. Their function is both aesthetic and practical. They hide imperfections on the original wall. They also provide a new surface that is tough and easy to clean.

The primary way they "work" is through their interlocking system. This mechanical design is what makes them a "paneling system" instead of just a simple covering. The edges are profiled to fit together perfectly. This design speeds up installation and creates a very clean look.

How Does the Interlocking System Function?

Most WPC panels use a tongue-and-groove (T&G) system. One side of the panel has a projecting ridge (the "tongue"). The other side has a matching recessed slot (the "groove"). This is how the system functions.

When I install these, this T&G system is the most helpful feature. You fix the first panel to the wall. Then, you slide the groove of the next panel onto the tongue of the first. This does two important things. First, it automatically ensures the panels are perfectly spaced. Second, it hides the fasteners. You drive screws or nails through the tongue. The groove of the next panel then covers those screws. The result is a seamless surface with no visible hardware.

Do WPC Panels Provide Any Insulation?

Yes, WPC panels provide a degree of thermal and acoustic insulation. The composite material itself helps to dampen sound. This can make a room feel quieter by reducing echo. The panels also create a new layer on the wall. This layer, and any small air gap behind it, adds a small amount of thermal resistance. It helps slow the transfer of heat or cold.

For projects needing serious insulation, you can find WPC wall panels with insulation. These products come with a layer of rigid foam pre-attached to the back. They are an excellent all-in-one solution for exterior walls or home theaters.

How Do Panels Protect the Wall Behind Them?

WPC panels act as a durable shield. They protect the drywall or plaster wall underneath from daily wear and tear. They are much harder to dent or scuff than a painted wall. This makes them ideal for high-traffic areas like hallways, entryways, or commercial spaces.

Their greatest protective quality is their water resistance. Because WPC is a waterproof and durable material, it blocks moisture. In a bathroom or basement, it prevents humid air or splashes from reaching the drywall. This stops mold, mildew, and rot before they can even start.

What Are the Main Types of WPC Wall Panels?

WPC panels are available in a wide array of styles. The main differences are in their profile (shape), finish, and intended use (indoors or outdoors). Choosing the right type is key to achieving your desired look.

What Is a Fluted WPC Panel?

A fluted panel is a panel with a 3D, slatted, or grooved surface. Instead of being flat, it has a repeating pattern of ridges and valleys. This is one of the most popular styles today. The fluted texture adds depth and shadow to a wall. It creates a strong visual interest and is often used for modern accent walls.

What Is a Flat WPC Panel?

A flat panel has a smooth, flat surface. It is designed to mimic traditional shiplap or V-groove paneling. These panels are excellent for covering large areas quickly. They provide a more subtle, classic look compared to the bold texture of fluted panels.

What Is the Difference Between Indoor and Outdoor Panels?

The application location is a critical distinction.

- Indoor Panels: These are designed for interior use. They come in a vast range of finishes, including realistic wood veneers or laminates. They are durable against indoor wear. They do not have the heavy-duty UV protection needed for direct sunlight.

- Outdoor Cladding: This is a much tougher product. Outdoor panels are "co-extruded," meaning they have an extra, durable shell bonded to the core. This shell is packed with UV stabilizers. It is engineered to resist fading, cracking, and weather damage for decades.

You can see examples of how these are used in our post on modern WPC wall cladding ideas.

What Are the Key Benefits of WPC Wall Panels?

The benefits of WPC wall panels all come from their unique composite structure. They combine the best parts of wood and plastic. They solve the biggest problems of most traditional wall materials.

- Exceptional Durability: WPC is highly resistant to impacts, scuffs, and scratches. It stands up to the traffic of a busy home or commercial space.

- 100% Waterproof: The plastic component makes the panels impervious to water. They will not swell, rot, warp, or grow mold. This is their biggest advantage over MDF or real wood.

- Very Low Maintenance: WPC panels do not need to be painted, stained, or sealed. Cleaning is simple. You just wipe them with a damp cloth.

- Simple Installation: The tongue-and-groove system is designed for ease. It is much faster and cleaner than installing drywall or tile. Many homeowners find it a manageable DIY project.

- Stylish Appearance: Panels are available in hundreds of colors, textures, and finishes. You can achieve the look of any wood species or a sleek, solid color.

- Sustainable Material: Most WPC is made from recycled materials. The wood is reclaimed sawdust, and the plastic is often post-consumer recycled.

Where Are WPC Wall Panels Commonly Used?

WPC panels are extremely versatile. Their blend of style and strength makes them suitable for almost any room or building.

Common Interior Applications:

- Living Room Feature Walls: This is the most popular use. A fluted WPC wall behind a TV or sofa creates an instant, high-end focal point.

- Bathroom Walls: They are perfect for bathroom walls outside the direct shower area. They add warmth and texture without the worry of water damage.

- Bedroom Headboard Walls: Installing panels on the wall behind the bed creates a beautiful, built-in headboard effect.

- Basement Renovations: Basements can be damp. WPC is an ideal choice for finishing basement walls because it is unaffected by moisture.

- Kitchens: They can be used as a backsplash (away from direct heat sources) or as a durable covering for a kitchen island front.

- Home Offices: A WPC wall makes a professional and quiet backdrop for video meetings.

Common Exterior Applications:

- Building Facades: Outdoor-grade WPC cladding is used as a modern, durable siding for homes.

- Soffits: It is often used to finish the underside of roof overhangs.

- Patio Walls: It can be used to create stylish and private accent walls in outdoor living spaces.

How Do You Install WPC Wall Panels?

The installation process is a key part of how WPC panels work. It is designed to be straightforward. The panels can be attached directly to a flat wall (like drywall) or to a wood framework (battens).

Here is a general step-by-step process. You can find a complete guide on how to install WPC wall panels on our site. Always check the specific manufacturer's instructions.

Step 1: Prepare Your Wall and Tools

Your wall must be clean, dry, and reasonably flat. Remove any old, loose wallpaper or flaking paint. Use a level to check the wall for any major high or low spots. Gather your tools: a tape measure, a level, a miter saw (or fine-toothed hand saw), a caulking gun, construction adhesive, and a brad nailer or screws.

Step 2: Acclimate the Panels

This is a step many people skip. Bring your boxed panels into the room where they will be installed. Let them sit for 48 hours. This allows the material to adjust to the room's temperature and humidity. It prevents any expansion or contraction problems after installation.

Step 3: Plan Your Layout

Measure the wall's width. Decide where your first panel will go. Starting in a corner is most common. You may want to plan the layout so you do not end up with a very thin, awkward-looking sliver on the other end.

Step 4: Cut and Install the First Panel

Measure the height of your wall. Cut your first panel to this length. For the very first panel, it is wise to cut the "groove" edge off. This gives you a flat, clean edge to place in the corner. Apply construction adhesive to the back of the panel in a long "S" shape. Press it firmly against the wall. Use your level to make 100% sure this first piece is perfectly vertical (plumb). Secure it by driving brad nails or screws through the "tongue" edge.

Step 5: Install the Remaining Panels

Take your second panel. Apply adhesive to the back. Firmly slide its "groove" over the "tongue" of the first panel. You should feel it lock in place. This action will hide the fasteners from the first panel. Secure this second panel by nailing or screwing through its exposed tongue. Repeat this process, working your way across the wall.

Step 6: Make Cuts and Install Trims

You will need to cut your last panel lengthwise to fit the final space. You will also need to cut holes for any outlets or light switches. Once all panels are on the wall, install the matching trim pieces. Corner trims and end caps cover the exposed edges and give the project a clean, finished look.

How Do WPC Panels Compare to Other Materials?

When choosing a wall covering, it helps to compare WPC to the alternatives.

- WPC is lower maintenance. Real wood is beautiful but requires staining, sealing, and refinishing. It can warp, crack, or rot in humid conditions. WPC provides the look of wood with zero of that maintenance.

- WPC is stronger and more rigid. PVC-only panels are very lightweight and 100% plastic. They can sometimes feel hollow or "cheap." The wood fibers in WPC give it a solid, durable feel and much better impact resistance. We have a detailed WPC vs. PVC wall panels breakdown.

- WPC is waterproof. This is the biggest difference. MDF (Medium-Density Fiberboard) is made of pressed wood fibers and glue. It acts like a sponge when it gets wet. It will swell, bubble, and fall apart. WPC is completely unaffected by water, making it the only choice for bathrooms or basements.

- WPC is easier and warmer. Tile is the king for high-water areas like inside a shower. On other walls, WPC is much easier, faster, and less messy to install. It is a DIY-friendly job, while tiling is a skilled trade. WPC also feels warmer to the touch than cold tile.

What Do WPC Wall Panels Cost?

The cost of WPC wall panels can vary. The price depends on the panel's quality, thickness, profile, and finish. Hollow-core interior panels will be the most affordable. Solid-core or co-extruded exterior panels will cost more.

You should expect WPC panels to have a higher upfront material cost than a can of paint or a roll of wallpaper. Their price is often comparable to mid-range tile or solid wood paneling. It is important to consider the long-term value. WPC panels do not have any repainting or refinishing costs. Their long lifespan means they often save money over time.

Are WPC Panels an Eco-Friendly Choice?

WPC panels are widely considered a sustainable or "green" building material. Their main environmental benefit comes from their composition.

The "wood" component is almost always made from recycled, reclaimed sources. This includes sawdust from lumber mills or recycled wood flour. The "plastic" component is also frequently made from post-consumer or post-industrial recycled plastics. Using these waste streams reduces the amount of material going to landfills. It also reduces the need for harvesting new, virgin resources.

The final product is not biodegradable. But its extreme durability and long lifespan are a form of sustainability. A product that lasts for 30 years creates less waste than one that must be replaced every 5-10 years.

Are There Any Disadvantages to WPC Panels?

No material is perfect. While WPC is a great product, there are a few considerations to keep in mind.

- Upfront Cost: As noted, the initial purchase price is higher than paint or wallpaper.

- Not for High Heat: WPC is a wood-plastic composite. It should not be installed right next to a high-heat source, like a fireplace insert or a gas stovetop, without checking the manufacturer's specific fire-rating and clearance.

- Appearance of Cheaper Panels: High-quality WPC looks very realistic. Very low-cost panels can sometimes have a repetitive, obviously printed-on wood grain.

- Must Use the Right Type: The biggest problem I have seen is user error. A person might install a cheap, indoor-only panel on an outdoor wall. The sun's UV rays will destroy it. This is not a failure of WPC; it is a failure to choose the right product for the application.

Frequently Asked Questions (FAQ)

Can you paint WPC wall panels?

Yes, you can paint WPC panels, but it requires correct prep. The surface must be very clean. You must use a high-quality primer designed to stick to plastic or composite materials. After the primer has cured, you can topcoat it with any good-quality acrylic latex paint.

How do you clean WPC panels?

Cleaning is one of their best features. For routine dust, a duster or a soft cloth is all you need. For smudges or grime, wipe the panels with a soft, damp cloth and a mild soap-and-water solution. Never use abrasive cleaners, steel wool, or harsh solvents.

Are WPC panels totally waterproof?

Yes, the panel itself is 100% waterproof. The composite material cannot absorb water. It will not swell or rot. The seams between panels are highly water-resistant. For a high-moisture area like a bathroom, it is a good practice to run a thin bead of clear silicone in the groove before clicking the next panel in.

How long do WPC wall panels last?

When installed correctly indoors, WPC panels can easily last for 25 years or more. Their lifespan is much longer than paint or wallpaper. Exterior-grade WPC cladding often comes with 20-25 year warranties against fading and damage.

Are WPC panels better than PVC panels?

They are different. PVC is 100% plastic, very light, and often cheaper. WPC contains wood, making it much more rigid, impact-resistant, and solid-feeling. Many people prefer the more substantial feel of WPC. You can compare WPC vs. PVC wall panels to see which is right for you.

The Modern Wall Solution

WPC wall panels are a true problem-solver. They "work" by combining the visual warmth of wood with the strength and water resistance of plastic. This composite material is formed into panels that are easy to install, thanks to their interlocking design.

They function as a durable, protective, and beautiful layer for your walls. They require almost no maintenance. Whether you are creating a single accent wall or finishing an entire room, WPC panels offer a reliable and stylish solution.

If you are ready to start planning your project, you can explore modular WPC wall systems or look at prefabricated WPC wall panel options.