WPC Wall Panel with Insulation: How It Improves Energy Efficiency

One key question we hear is about the WPC wall panel with insulation: how it improves energy efficiency in a home. WPC panels are known for their style, but their impact on a room's comfort and your energy bills is an equally important, and often misunderstood, benefit.

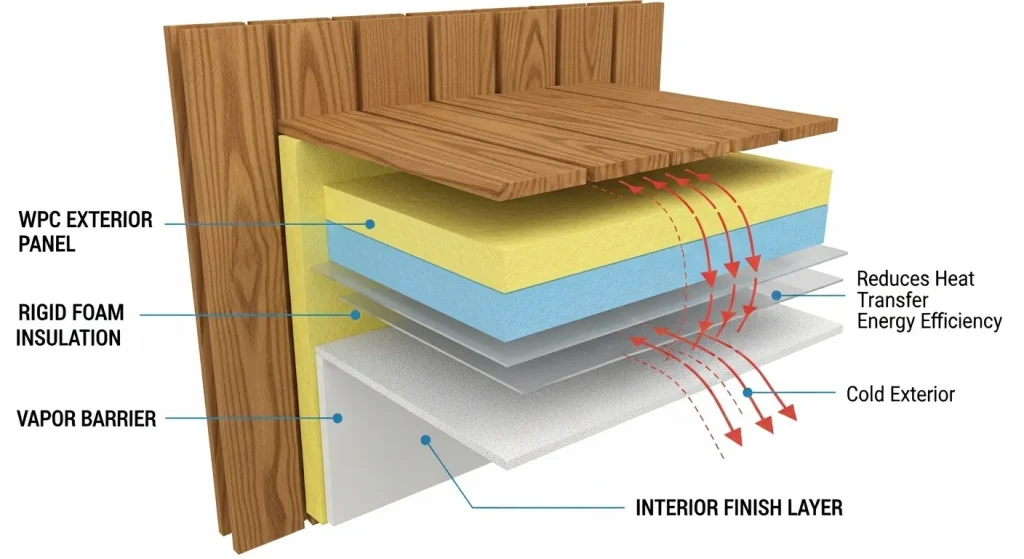

The truth is, these panels improve your home's energy efficiency in two ways. First, the panel material itself has inherent insulating properties. Second, the best-practice installation method creates a perfect space to add extra, high-R-value insulation. This combination is what turns a cold, basic wall into a high-performance, energy-saving surface.

This guide explores both of these benefits. We will cover the panel's built-in thermal and acoustic properties, and then walk through a step-by-step guide on how to pair WPC panels with rigid foam insulation for maximum energy savings. For a full overview of the material itself, see our WPC wall panels guide.

Do WPC Wall Panels Have Inherent Insulation?

Yes, WPC panels provide both thermal and acoustic insulation right out of the box.1 Their dense, solid composite core, made of wood fibers and plastic resins, slows the transfer of heat and sound.2 This makes them a superior insulator compared to thin drywall or hollow PVC panels.

The magic is in the material mix. If you've ever held a solid WPC panel, you'll know it has a substantial, heavy feel. This is a key part of its insulating power.

- Wood Fibers: The wood fibers (which are a core part of what are WPC wall panels) are natural insulators. Wood has a cellular structure that traps air, which is why it's a poor conductor of heat.3

- Plastic Resin: The plastic resin binds these fibers into a very dense, non-porous composite. This density is fantastic for blocking sound waves.

When you install a WPC panel, you are adding another "layer" of protection to your wall. It's an incremental improvement that, when combined with your wall's existing insulation, helps to create a more stable and comfortable indoor environment.

What Is an R-Value and Does WPC Have One?

R-value is a standard measurement of a material's resistance to heat flow.4 A higher R-value means better insulation.5 WPC panels do have a positive R-value, though it's important to see it as a "bonus" rather than a primary insulating solution.

A typical WPC wall panel might have an R-value between R-1 and R-2. This may not sound high compared to the R-15 fiberglass inside your walls, but it's a significant addition.

Consider this:

- A standard 1/2-inch drywall panel has an R-value of just R-0.45.

- A hollow PVC panel has an R-value that is almost negligible.

When you add an R-1.5 WPC panel over your R-0.45 drywall, you are more than tripling the insulating value of the wall's surface. This helps to reduce thermal bridging (which we'll cover later) and makes the wall feel warmer to the touch.

Are WPC Panels Good for Sound Insulation?

Yes, WPC panels are exceptionally good at acoustic (sound) insulation.6 The high density of the solid composite core is very effective at blocking airborne noise.7 Fluted or 3D panel designs also help to break up and absorb sound waves (echo) within a room.8

This is one of the most immediate benefits I've experienced. I installed a modern WPC wall cladding (a fluted style) in my home office. The room had a noticeable echo and I could easily hear noise from the rest of the house. After the installation, the room became dramatically quieter. The echo was gone, and the outside noises were muffled.

WPC panels fight sound in two ways:

- Sound Blocking (Mass): The sheer density of the panel creates a barrier that noise struggles to get through.9 This is called "sound transmission loss."

- Sound Absorption (Shape): This applies mostly to fluted or slatted designs. The uneven surfaces break up sound waves, preventing them from bouncing around the room.10 This makes a room feel less "hollow" and more comfortable.

This makes WPC panels a perfect choice for home theaters, bedrooms, nurseries, or any office where you need quiet to concentrate.

The Real Benefit: Adding Insulation Behind WPC Panels

The best way to achieve a major improvement in energy efficiency is to add dedicated insulation behind the WPC panels. The standard installation method for these panels, which often uses furring strips, creates a perfect, built-in cavity for rigid foam insulation boards.

This is the "pro-level" secret to a high-performance WPC wall. The panel itself adds a little insulation. The air gap adds a little more. But filling that air gap with a 3/4-inch or 1-inch rigid foam board? That's a game-changer. This "WPC and foam sandwich" is how you turn a cold basement wall into a warm, dry, finished part of your home.

What Is a Thermal Break?

A thermal break is a material that does not conduct heat well.11 It is used to separate the inside and outside of a building's structure. Adding rigid foam insulation behind WPC panels creates a "continuous thermal break" that stops heat from passing through the wall.

This is a critical concept. In a standard wall, your wooden studs (the 2x4s) are a "thermal bridge." Wood is a better insulator than metal, but it's a terrible insulator compared to fiberglass.

In winter, heat from your home's interior "bypasses" the insulation by traveling right through the wood studs, like a highway. You can often see this on a cold day; the wall will be colder where the studs are.

When you install a continuous layer of rigid foam over the studs, you stop this "highway." You create an unbroken blanket of insulation. This is how a WPC-plus-foam system dramatically improves your home's efficiency.

How to Install WPC Panels with Rigid Foam Insulation (Step-by-Step)

To install a WPC wall panel with insulation, you first attach 1x3-inch furring strips (wood battens) vertically to your wall. Then, cut rigid foam (XPS or Polyiso) panels to fit snugly between those strips. Finally, install the WPC wall panels directly onto the furring strips, creating an insulated "sandwich."

This method is surprisingly straightforward and is the best way to get a perfectly level, high-performance wall.

Step 1: Gather Your Materials

- WPC wall panels and trim

- 1x3 furring strips (wood or metal)

- Rigid foam insulation (XPS or Polyiso)

- Construction screws (long enough to go through the furring strips and into the studs)

- Tape measure, level (a laser level is very helpful), and a saw

- Utility knife for cutting foam12

Step 2: Locate Studs and Attach Furring Strips

Use a stud finder to locate and mark all the vertical studs on your wall.13 Attach your 1x3 furring strips vertically onto the wall, screwing them through the drywall and into the studs. Place them 16 inches on center (so they align with your studs).

Pro-Tip: This is your chance to make a wavy, uneven wall perfectly flat. As you attach the furring strips, use a long level. If the wall bows inward, add small "shims" (thin pieces of wood) behind the strip before you screw it in. When you are done, you will have a perfectly flat, plumb "frame" for your new wall.

Step 3: Cut and Fit the Rigid Foam Insulation

Now you have a grid of 1x3s on your wall with empty spaces between them. Measure the thickness of your furring strips (they are typically 3/4-inch thick). Buy rigid foam insulation of the same thickness.

Measure the space between the strips (about 14.5 inches) and cut the rigid foam boards with a utility knife. Fit them snugly into the cavities. The foam should be flush with the face of the furring strips.

Step 4: Install the WPC Panels

With your insulated frame complete, the hard part is over. Now, you just install the WPC panels. Attach them directly to the furring strips, not the drywall behind them.

Follow the manufacturer's instructions. This usually involves a starter strip at the bottom and then locking the tongue-and-groove panels as you move up or across the wall. The panels will "float" over the foam, and the installation will be incredibly secure.

How Exactly Does This System Improve Energy Efficiency?

This WPC and foam "sandwich" system stops thermal bridging. Heat can no longer escape through the cold-conductive wood studs in your wall. This creates a continuous, unbroken blanket of insulation, keeping your room warmer in winter and cooler in summer.

This method tackles all three types of heat transfer:

- Conduction: It stops heat from "conducting" through the studs by covering them with foam.

- Convection: It eliminates any air-leaky drafts by creating a solid, sealed panel surface.

- Radiation: The foam's surface (especially foil-faced) can reflect radiant heat.14

Stopping Your Heating Bills from Climbing

In the winter, your heating system's job is to replace the heat that is lost to the cold outside. A significant portion of that heat is lost through your walls.15 An uninsulated or poorly insulated wall is like leaving a window open.

By adding this continuous layer of insulation, you are "blanketing" your home. The heat your furnace produces stays in the room longer. Your heating system runs less often, which directly translates to lower energy bills.16 The wall will also feel warm to the touch, increasing your home's physical comfort.

Keeping Your Home Cool in the Summer

This system works just as hard in the summer. Heat gain is the enemy of your air conditioner. Hot, outside air "soaks" into your home, forcing your AC to work overtime.

The WPC and foam system stops this. It acts as a barrier, preventing the sun's heat from "radiating" through the wall and into your house.17 This keeps your home's interior temperature more stable, allowing your air conditioner to run less.18

Where Is This Insulated WPC System Most Effective?

This method is most effective on exterior walls, especially in basements. Solid concrete or block basement walls are a massive source of heat loss. Applying foam and WPC panels is a perfect, all-in-one solution for insulating and finishing a basement.

- Basements (The #1 Use): A concrete wall is an "energy vampire." It is cold, damp, and porous. The WPC-and-foam system is the perfect solution. The foam insulates. The WPC is 100% waterproof, so it cannot grow mold (a huge benefit of WPC wall panels). It's an all-in-one, high-performance basement finishing system.

- Older Homes: Many older homes were built with little or no insulation in the walls.19 This system is a fantastic way to retrofit insulation from the inside without tearing out all the old plaster.

- Home Theaters: For the dual benefit. The foam provides thermal insulation, while the WPC panel provides superior acoustic insulation.

- Any "Cold" Exterior Wall: Do you have a living room wall that is always cold to the touch in winter? That is an exterior wall. Adding this WPC system will make that room instantly more comfortable.

WPC Insulation vs. Other Wall Materials

The WPC-with-foam system offers a better R-value and a finished look in one step. Standard drywall requires a multi-day process of mudding, sanding, and painting, and it is not waterproof. Hollow PVC panels offer almost no insulation.

Here is a simple comparison:

| Wall System | Inherent R-Value | Sound Insulation | Waterproof? | Install Complexity |

| WPC + 3/4" Foam | High (Adds ~R-5) | Excellent | Yes | Medium (DIY-able) |

| WPC Panel (Alone) | Low (R-1 to R-2) | Good | Yes | Easy |

| Drywall + Paint | Very Low (R-0.5) | Poor | No | High (Multi-step) |

| Hollow PVC Panel | Very Low (Negligible) | Poor | Yes | Easy |

| Exposed Brick | Very Low (High mass) | Poor (Reflects) | No (Porous) | N/A |

As you can see, the WPC-plus-foam system is a clear winner for performance. It's the only option that is high-insulation, waterproof, sound-dampening, and a final finish all in one. A WPC vs PVC wall panel comparison shows WPC's solid core is the clear winner for insulation.

Can WPC with Insulation Replace My Wall's Main Insulation?

No. A WPC panel with 1 inch of foam is a supplemental system. It adds to your existing insulation; it does not replace it. Your home's main wall cavities still need their code-required R-13 to R-21 of fiberglass or spray foam insulation.

Think of this WPC system as an "insulating jacket" you put over your wall's "sweater." It's designed to stop drafts, add an extra layer of R-value (R-3 to R-7, depending on the foam), and, most importantly, stop that critical thermal bridging. It's an improvement, not a replacement.

A Final Summary on WPC, Insulation, and Energy Efficiency

A WPC wall panel is an energy-efficient choice, but its power is multiplied when installed correctly.

- On its own, a WPC panel provides good acoustic insulation and a small thermal R-value bonus.20

- When installed with furring strips and rigid foam, it becomes a high-performance insulating system.

This "sandwich" method stops thermal bridging, adds R-5 or more to your wall, and creates a finished, waterproof, and durable surface in one go. This is how a WPC wall panel with insulation improves energy efficiency: it's a complete system that makes your home more comfortable and helps lower your energy bills.