Modular WPC Wall Systems Explained

Modular WPC wall systems are a high-performance, kitted solution for finishing interior walls. They take the benefits of standard WPC panels and add a layer of precision and installation speed. Unlike simple planks, a modular system is a complete set of interlocking components designed to work together perfectly.

If you are a contractor, developer, or homeowner who values a fast, clean, and flawless installation, this is a product you need to know. This guide breaks down what modular WPC systems are, how they are different from standard panels, and why they are a smart choice for modern construction.

What Are Modular WPC Wall Systems?

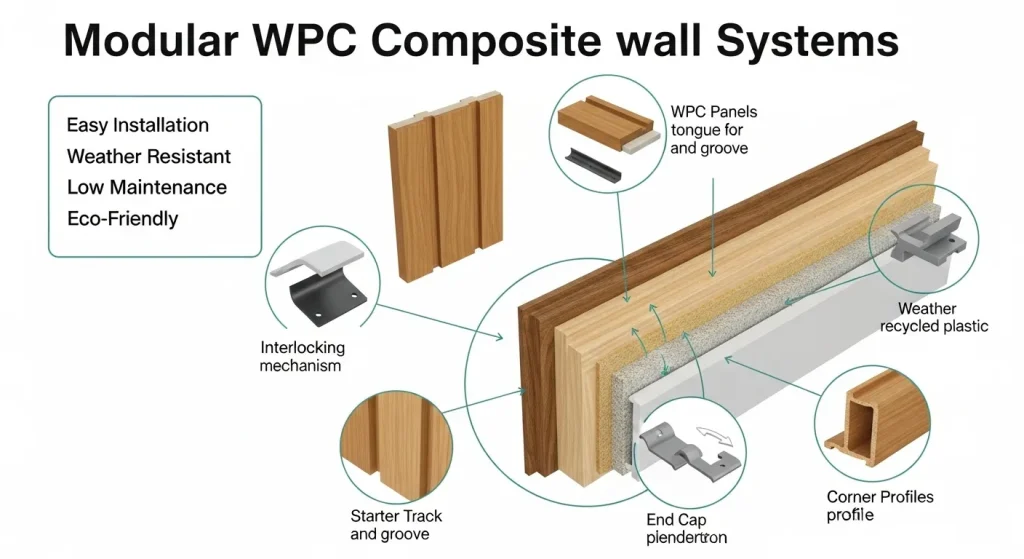

A modular WPC wall system is a complete, kitted set of interlocking components. It includes not just the wall panels but also the mounting tracks, clips, and trim pieces. These parts are designed to fit together perfectly for a fast, flawless installation.

Think of it as a "wall-in-a-box" solution. Instead of buying individual planks and figuring out the mounting and trim separately, a modular system provides everything you need. The core material is still WPC (Wood-Plastic Composite), which you can learn about in our guide on what are WPC wall panels. The "modular" part refers to the installation method and the component-based approach.

How Are Modular Systems Different from Standard WPC Planks?

Standard WPC planks are individual boards, usually tongue-and-groove, that you cut and attach directly to the wall.2 A modular system is a complete kit with a hidden mounting framework (like tracks or clips) that the panels snap onto, creating a more integrated, often "floating," look.

I've installed both, and the experience is night and day. The standard how to install WPC wall panels method often involves a lot of construction adhesive. You have to be very careful with your level and spacing on every single plank.

My first time with a modular system, I was struck by the lack of glue. The work is all in the track. Once the track is level, every panel just "clicks" into place perfectly. The speed and precision are unmatched.

Here is a direct comparison:

| Feature | Modular WPC System | Standard WPC Planks |

| Components | Full kit: Panels, tracks, clips, integrated trim. | Panels only. Trim and adhesive bought separately. |

| Mounting | Hidden tracks or clips (mechanical fit). | Glue, brad nails, or screws (direct to wall). |

| Installation | Extremely fast, clean, and precise. | Slower, messier (if using glue), relies on installer skill. |

| Alignment | "Forced" perfection. The tracks set the spacing. | Manual. Requires careful leveling for each plank. |

| Repair | Easy. A single panel can be "un-clicked" and replaced. | Very difficult. Glued panels must be destroyed to remove. |

| Air Gap | Creates a built-in air gap behind the panel. | Sits flush against the wall (unless furring strips are built). |

| Best For | Commercial projects, high-end homes, media walls. | Standard DIY projects, budget-conscious feature walls. |

What Are the Key Components of a Modular WPC System?

A typical modular WPC system includes three main parts: the wall panels (fluted, flat, etc.), a hidden mounting system (like metal tracks or clips), and matching trim pieces. These trims (corners, edges, bases) are designed to integrate perfectly with the panels.

Let's look at each part.

- 1. The Wall Panels: This is the "face" of the system. These are the WPC panels themselves. They come in a variety of styles, from flat to the very popular modern WPC wall cladding ideas like fluted or slatted designs. The key difference is that the back of the panel is engineered to "click" into the mounting system.

- 2. The Mounting System (The "Secret Sauce"): This is what makes it modular. It is usually a set of metal or high-density plastic tracks. You screw these tracks to the wall studs or a flat surface. The system also includes special starter clips, connector clips, and locking clips that ensure the panels are held securely.

- 3. Integrated Trim: This is the finishing touch. A good modular system comes with a full set of matching trim pieces. This includes inside/outside corner trims, end caps (J-trims), and sometimes even baseboard covers. These trims are not just glued on top; they are designed to snap onto the tracks or panels for a truly clean, integrated look.

What Are the Main Benefits of Choosing a Modular System?

The main benefits are installation speed, precision, and ease of replacement. The track and clip systems are much faster than traditional glue-up methods. They also allow for easy removal of a single panel for repairs, which is impossible with adhesive.

Let's explore these benefits in more detail.

Installation Speed

For a contractor or developer, time is money. A modular system can be installed in a fraction of the time of other wall finishes. Once the tracks are up, a two-person team can "click" hundreds of square feet of wall into place in a single day. There is no mudding, sanding, painting, or drying time.

Perfect, Consistent Alignment

The tracks or clips force perfect spacing and alignment. You do not have to worry about a panel slowly drifting off-level as you move across the wall. If your first track is level, your entire wall will be level. This removes a huge amount of potential human error.

Ease of Repair and Access

This is a massive, often overlooked, benefit. If a panel gets damaged, you can use a special tool (or careful prying) to unlock and remove just that one panel. You then click a new one into its place. With a glued-on wall, a single damaged panel means a major, destructive repair job. This also means you can create access panels for hidden plumbing or wiring.

A Cleaner, No-Mess Installation

Because the primary mounting method is mechanical (clips and tracks), there is no need for messy construction adhesive. There are no glue fumes, no risk of smearing glue on the finished panel, and no "cure" time. You can use the room immediately after installation.

Better for Problem Walls

A modular system with tracks can be installed over walls that are not perfectly flat. The tracks (when shimmed correctly) create a new, perfectly plumb plane. Trying to glue panels to a wavy, uneven wall is a nightmare. This system solves that problem.

Hiding Wires and Adding Insulation

The tracks create a natural air gap between the wall and the WPC panel. This space is a game-changer. I recently used a modular system for a media wall. The best part was the channel behind the panel. We ran all the HDMI and power cords right in that gap. The wall looks completely clean.

This gap is also perfect for adding WPC wall panels with insulation in the form of rigid foam boards. This boosts the wall's thermal and acoustic properties.

How Do Modular Systems Compare to Prefabricated Panels?

Modular systems are kitted, interlocking components you assemble on-site.3 Prefabricated WPC panels are large, custom-built wall sections that arrive pre-assembled. "Modular" is about on-site assembly; "prefabricated" is about off-site assembly.

- Modular: You get a box of tracks, clips, and 10-foot panels. You cut and assemble them on the wall. This gives you on-site flexibility.

- Prefabricated: You give the company your exact wall dimensions. They build a 10-foot by 8-foot section in their factory and ship it to you. You just lift it and attach it.

Prefabricated WPC wall panels are best for very large, repetitive jobs, like a hotel or office building, where speed is the number one priority. Modular systems are a perfect middle-ground, offering speed and on-site flexibility.4

How Do You Install a Modular WPC Wall System?

Installation involves attaching a mounting track or rail system to the wall studs or a flat surface. The WPC panels are then "clicked" or "snapped" onto these tracks. The process is finished by snapping on integrated trim pieces at the corners and edges.

While each system is slightly different, here is a general step-by-step guide.

Step 1: Plan and Prepare Your Wall

Clear the wall. Locate all your wall studs and mark them with a pencil. Use a laser level to plan where your first and last tracks will go. Your wall must be dry and structurally sound.

Step 2: Install the Mounting Tracks

This is the most important step. Get this right, and the rest is easy. Start by installing the main vertical or horizontal tracks. Screw them directly into the wall studs. Use a laser level to ensure every track is perfectly level (horizontal) or plumb (vertical). If your wall is uneven, use shims behind the tracks to make them perfectly flat.

Step 3: Install Starter Clips

Most systems have a "starter clip" or a special starter trim. This piece is installed at the bottom or side of the wall and provides the first "groove" for your panels to lock into.

Step 4: Cut and Snap-on the First Panel

Measure and cut your first WPC panel to the correct height. Use a fine-tooth blade for a clean cut. Insert the panel into the starter clip and then firmly "click" or "snap" it onto the tracks. You should hear or feel it lock into place.

Step 5: Continue Across the Wall

Take your next panel. Lock its groove into the tongue of the first panel, then snap it onto the tracks. The "click-lock" action is fast and very satisfying. The panels will automatically be spaced and aligned by the track system.

Step 6: Install the Final Trims

When you reach the end of the wall or a corner, you will cut the last panel to fit. Then, you will install the final trim piece. This is usually an end cap or a corner trim. These trims are designed to snap onto the tracks or the last panel, hiding all cut edges and fasteners.

This entire process is much faster and cleaner than the traditional adhesive method.

What Are the Common Applications for Modular WPC?

Modular WPC systems are very popular in commercial spaces like offices, hotels, and restaurants due to their speed and durability.5 In homes, they are ideal for high-end feature walls, media centers, and basements where quick, clean installation is valued.6

- Commercial Use: This is their primary market. Hotels, offices, and retail stores love them. They can renovate a space overnight with minimal disruption. The durability handles high traffic, and the repairability is a major long-term-cost-saver.

- Residential Use: In homes, these systems are perfect for:

- Media Walls: The channel for hiding wires is a huge benefit.

- Basements: The air gap is great for a basement, as it allows the wall to breathe. It also installs perfectly over concrete block walls.

- Home Theaters: The acoustic-insulating properties are a big plus.

- High-End Feature Walls: For the homeowner who wants a "pro" finish without the mess.

WPC Modular Systems vs. Other Materials (A Comparison)

Modular WPC is a premium-finished wall system. It's faster than drywall and more durable than PVC or wood.

- vs. Drywall: A modular WPC wall is a "one-step" process. You install it, and you are done. Drywall is a multi-day process of hanging, mudding, sanding, priming, and painting.7 WPC has no dust, no fumes, and is far more durable.

- vs. Modular PVC: PVC is also modular, but it's a lighter, less-durable material. WPC is a high-density, solid composite.8 It resists dents far better and has a more premium, "solid" feel. Our WPC vs PVC wall panels article explores this.

- vs. Traditional Wood: A modular WPC system gives you the look of wood without the maintenance. It will not warp, rot, or split. It is waterproof and pest-proof. It also installs much faster than cutting and face-nailing individual wood planks.

Are There Downsides to Modular WPC Systems?

The main downsides are cost and design limitations. Modular systems are a premium product and cost more than basic planks. Your design is also limited to the specific panels, colors, and trims offered within that manufacturer's system.

- Cost: This is the biggest factor. You are not just buying panels; you are buying an engineered system. The tracks, clips, and integrated trims all add to the price. It is a premium product with a premium price tag.

- Proprietary Systems: You are locked into a manufacturer's "ecosystem." You cannot use one brand's panels with another brand's tracks. This limits your flexibility.

- Availability: You may not find these systems at your local big-box store. They are often sold through specialty building suppliers or commercial distributors.

Are Modular WPC Wall Systems a Good Investment?

Yes, for the right project. A modular system is a good investment if your priority is speed, a perfect finish, and long-term durability. While the upfront cost is higher, you save significantly on installation labor and future maintenance.9

When you factor in the cost of a drywall installer, a taper, a sander, and a painter, the "all-in-one" cost of a modular WPC system becomes much more competitive.

For a high-end, modern look, the benefits of WPC wall panels—combined with the intelligence of a modular track system—create a wall finish that is hard to beat.

Are Modular WPC Systems the Future of Walls?

Modular WPC wall systems represent a major step up from simple planks. They offer a fast, precise, and durable way to create high-end feature walls.

They bridge the gap between simple DIY planks and expensive, custom-built millwork. For contractors and homeowners who want a professional result without the traditional mess and timeline, a modular system is one of the smartest solutions on the market.

To learn more about the base material that makes this all possible, see our complete WPC wall panels guide.