Structural PVC Wall Panels: Features and Applications

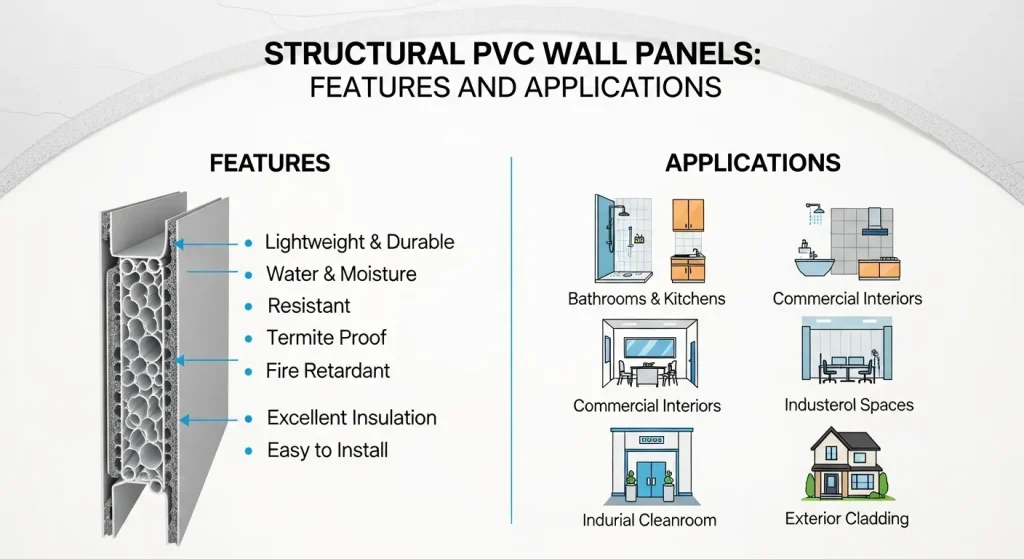

When you hear "PVC wall panel," you might think of the lightweight, decorative panels for a home bathroom. This article is not about those. This guide explores the structural pvc wall panels features and applications that building professionals, facility managers, and contractors rely on. These are a different class of material.

These are the heavy-duty, reinforced panels you see in car washes, commercial kitchens, and hospitals. They are engineered for one purpose: to provide a durable, hygienic, and waterproof wall that can withstand high abuse.

As a commercial installer, I have seen these panels solve the biggest challenges in demanding environments. Standard drywall turns to mush with water. Tile grout grows bacteria. Painted steel rusts. Structural PVC is the engineered solution that addresses all these failures. This guide is a deep dive based on that field experience.

What Are Structural PVC Wall Panels?

Structural PVC wall panels are heavy-duty, reinforced, solid-core or dense-foam-core plastic panels. They are designed for extreme durability and impact resistance.1 Unlike standard hollow-core panels, structural PVC is engineered to replace drywall or other wall-cladding systems. It provides a finished, waterproof, and hygienic surface in one step.

These panels are the workhorses of the construction world. They are not chosen for their intricate designs. They are chosen for their function. This is a crucial distinction. We are not talking about a thin decorative cover; we are talking about a robust building component.

How Are Structural Panels Different from Standard PVC?

The main difference is the core. Standard PVC panels are hollow, lightweight, and designed for residential, low-impact areas. Structural PVC panels are solid or have a dense, reinforced core. This makes them heavy, rigid, and extremely resistant to impacts.

Think of it this way: a standard hollow panel is like a kayak. It is light, waterproof, and perfect for its job. But a structural panel is like the hull of a commercial fishing boat. It is built to be hit, to resist pressure, and to last for decades in a harsh environment. I have seen a misplaced chair puncture a hollow-core panel. I have seen a 200kg food cart bounce off a structural panel without leaving a mark.

This difference is the key to understanding all what are pvc wall panels and their different grades.

Comparison: Structural PVC vs. Standard PVC

| Feature | Structural PVC Panel | Standard Hollow-Core PVC Panel |

| Core | Solid, dense foam, or reinforced | Hollow, with fluted channels |

| Impact Resistance | Very High. Can withstand carts, gurneys. | Low. Can be punctured or cracked. |

| Weight | Heavy. | Very Lightweight. |

| Primary Use | Commercial, industrial, agricultural | Residential bathrooms, ceilings |

| Installation | Mechanical fasteners (screws) | Adhesive (glue-up) |

| Cost | High ($$$-$$$$) | Low ($$) |

What Are the Core Features of Structural PVC Panels?

The core features of structural PVC panels all stem from their heavy-duty construction. They are built to solve the problems that destroy lesser materials. Their main features are impact resistance, 100% waterproof construction, and a hygienic, non-porous surface. They are also highly resistant to chemicals.

How Do They Achieve Such High Impact Resistance?

They achieve high impact resistance from their solid or dense core. Unlike a hollow panel that can be crushed, a structural panel's core is a solid mass of high-density PVC foam or a reinforced plastic matrix. This solid "body" distributes the force of an impact.

This is not a theoretical feature. It is the main reason they are specified. In a hospital corridor, gurneys and carts hit the walls all day. In a warehouse, forklifts clip corners.

Are They Truly 100% Waterproof?

Yes. The panels are made from 100% Polyvinyl Chloride plastic. The material itself is non-porous and cannot absorb water.2 It will not swell, rot, warp, or grow mold.3

This is a massive advantage over "water-resistant" drywall or cement board. Those materials can still wick moisture, leading to mold behind the wall. Structural PVC creates a complete, impenetrable barrier. This is why it is the number one choice for car washes and food processing plants.

What Makes Them a Hygienic Wall System?

Structural PVC panels are hygienic because they are non-porous and seamless.

- Non-Porous Surface: Bacteria, mold, and viruses have no microscopic pores to hide in. This is a stark contrast to tile grout, which is a cement-based, porous material that is a known breeding ground for germs.

- Seamless Installation: The panels lock together with tight, interlocking tongue-and-groove edges.6 When sealed with a bead of silicone or a hot-weld, they form one massive, continuous surface. There are no cracks or crevices for dirt and bacteria to collect.7

This is why they are specified for cleanrooms and surgical centers. They can be sanitized to a medical-grade standard.

Are They Resistant to Chemicals and Stains?

Yes. Structural PVC is highly resistant to a wide range of chemicals, acids, and alkalis. This is a critical feature for industrial or commercial use.

- Commercial Kitchens: They will not stain from grease, food acids, or blood.

- Hospitals: They can be cleaned with harsh disinfectants and bleach solutions without fading or degrading.

- Factories: They can withstand chemical splashes and industrial cleaners.

- Car Washes: They are unaffected by harsh soaps, waxes, and road salts.

You can learn more about how to clean and maintain PVC wall panels made for this kind of abuse.

What Is Their Fire Rating?

Most high-quality structural PVC panels have a Class A (or Class 1) Fire Rating per ASTM E-84. This is a critical specification for any commercial or public building.

A Class A rating means the material has a very low flame spread and smoke development index. It will not act as a fuel source in a fire. As a specifier, I will never use a panel in a public space that does not have this certification. It is a non-negotiable for safety and building codes.

Where Are the Top Applications for Structural PVC Panels?

The top applications for structural PVC panels are any high-abuse, high-moisture, or high-hygiene environment. They are a functional product for the toughest jobs. You will not find them in a hotel lobby, but you will find them in the kitchen behind the lobby.

Application 1: Commercial Kitchens and Food Processing

This is a primary application. These panels are a health inspector's dream.

- Why they are used: They meet USDA and FDA requirements for a "cleanable" surface. The seamless, non-porous surface is easy to spray down and sanitize, preventing bacteria growth.10

- My Experience: I have replaced many FRP (Fiberglass Reinforced Panel) walls in kitchens. The owners were tired of the FRP seams delaminating or the underlying board turning to mush. Structural PVC is a one-piece, waterproof solution that does not have these failure points.

Application 2: Car Washes

This is the ultimate wet environment.

- Why they are used: They are 100% waterproof.11 They are resistant to the harsh chemicals in car soaps and waxes. They will not rust like corrugated steel panels or rot like wood. The bright white finish also reflects light, making the bay brighter.12

Application 3: Agricultural Buildings (Dairies, Kennels, Stables)

These spaces require daily wash-downs and high durability.

- Why they are used: They are non-porous and will not absorb animal waste or odors.13 They can be pressure-washed daily without degrading.14 They are tough enough to withstand being kicked or rubbed by animals.

Application 4: Healthcare, Labs, and Cleanrooms

These are high-hygiene, high-traffic applications.

- Why they are used:

- Hygiene: The seamless, non-porous surface is critical for disinfection.15

- Durability: They resist impacts from gurneys, wheelchairs, and supply carts in corridors.

- Chemical Resistance: They will not be damaged by the harsh chemical cleaners used in hospitals.16

Application 5: Industrial and "Back-of-House" Areas

This includes warehouses, loading docks, equipment rooms, and public restrooms.

- Why they are used: Pure function. They are a durable "liner" for a wall. They protect the underlying structure from impacts, moisture, and dirt.17 It is a "one-and-done" install that requires zero maintenance.

Application 6: High-End Garages and Workshops

While most applications are commercial, there is a growing residential market for structural PVC.

- Why they are used: They provide a finished, bright, and easy-to-clean wall for a high-end garage or workshop. They are far more durable than drywall and are unaffected by melting snow or road salts dripping off a car.

What Are the Design and Aesthetic Features?

The design features of structural PVC panels are function-first. They are not meant to be decorative. The "design" is in their clean, bright, and seamless appearance.

What Colors and Finishes Are Available?

The vast majority of structural PVC panels come in white or light gray.

- Why white?

- Hygiene: It shows dirt, making it easy to see what needs to be cleaned.

- Light: It has a high light-reflective value (LRV), making a space feel brighter and cleaner.

- Finish: The standard finish is a smooth, low-sheen, or matte surface. This is easy to wipe down. Some panels have a slight "pebbled" or "stippled" texture to hide minor scuffs.

Can You Paint Structural PVC Panels?

Yes, you can, but it is not recommended in most of their core applications.

- The Problem: Painting a panel can compromise its hygienic, non-porous surface. Paint can chip, peel, or scratch. This creates crevices for bacteria to hide.

- When It Is OK: If you are using them in a "dry" application like a workshop or garage, you can paint them.

- The Process: You must follow a strict process:

- Clean the panels.

- Lightly scuff the surface with fine-grit sandpaper.

- Apply a high-adhesion primer designed for plastic.

- Topcoat with a quality acrylic latex paint.

- For more on this, see our guide on paintable PVC wall panels.

How Are Structural PVC Panels Installed?

Installation of structural PVC is a mechanical process. It is not a "glue-up" project like lightweight panels. These heavy panels are fastened directly to the building's structure.

What Is the General Installation Process?

The process involves screwing the panels to a solid substrate.

- Prepare the Wall: The wall must be flat. This is key. You cannot "bend" these rigid panels over a bowed wall. The best substrate is either plywood sheathing or exposed wall studs (wood or metal).

- Install Starter Trim: A "J-trim" or base trim is installed at the bottom of the wall, perfectly level.

- Cut and Place the First Panel: Panels are cut to height using a circular saw or track saw. The first panel is set in the trim and checked to be perfectly plumb (vertical).

- Fasten the Panel: This is the critical step. You use non-corrosive screws (stainless steel) and drive them through the panel's pre-drilled nailing flange, directly into the studs.

- Interlock and Repeat: The next panel's groove slides over the first panel's tongue, hiding the screws. This panel is then fastened on its open edge. This process is repeated.

- Finish with Trims: All corners and edges are finished with matching PVC trims (corner trims, J-trims) to create a sealed, finished system.

Do They Need Battens or Plywood Backing?

I strongly recommend a solid backing.

- Direct-to-Stud: You can install these panels directly to studs, and this is common.18 The panels are rigid enough to span the 16-inch or 24-inch gaps.19

- The Pro-Method (My Recommendation): I always advocate for installing them over 5/8" (15mm) plywood. Why?

- A Perfect Plane: Plywood creates a perfectly flat, solid wall.

- Superior Fastening: You can place your fasteners anywhere, not just on the studs.

- Impact Strength: The plywood + PVC combination is almost indestructible.

- Do not install them over uneven concrete block or crumbly plaster. It will not work.

How Do They Compare to Other Commercial Wall Systems?

This is the question every architect and builder has to answer. Why choose this?

Structural PVC vs. FRP (Fiberglass Reinforced Panels)

This is the classic showdown. FRP has been the "kitchen" standard for decades.

- The Problem with FRP: FRP is awful to install. Cutting it creates fine fiberglass dust that is an irritant. The panels are thin and wavy. The plastic trims are ugly and crack. The adhesive can fail.

- The PVC Advantage: Structural PVC is a complete system. It is thicker and more rigid. It cuts cleanly with standard wood tools (no dust). It has a built-in fastening flange. It is a faster, cleaner, and more modern installation.

Structural PVC vs. WPC (Wood-Plastic Composite)

WPC and structural PVC are rarely in direct competition. They have different jobs.

- WPC: This is an aesthetic product. It is used in lobbies, offices, and restaurants to mimic wood. It is durable, but not designed for chemical wash-downs.

- PVC: This is a utility product. It is used in kitchens, car washes, and hospitals.

- See our full PVC vs. WPC wall panels comparison for more.

Structural PVC vs. Ceramic Tile

Tile is durable, but its weakness is grout.

- The Grout Problem: Grout is porous, cement-based, and a nightmare to keep clean.23 It stains, cracks, and harbors bacteria.

- The PVC Advantage: PVC is seamless.24 It is one solid surface. The installation is also 5x faster and does not involve wet mortar or messy grout.

Structural PVC vs. Painted Drywall or Epoxy Paint

This is not a fair fight in a wet environment.

- The Problem: "Water-resistant" drywall will fail with constant exposure. Epoxy paint on drywall will chip and peel. Once a chip occurs, water gets behind the paint, and the drywall is destroyed.

- The PVC Advantage: PVC is a solid sheet of waterproof material.25 There is no paint to chip, no drywall to rot.

What Are the Cost and Sustainability Considerations?

What Is the Total Cost of Ownership (TCO)?

Structural PVC panels have a high upfront material cost but a very low Total Cost of Ownership (TCO).

- Material Cost: Expect to pay more per square meter than for any other option besides high-end tile.

- Installation Cost: Labor is fast and requires no specialized wet-trade-skills. This is a major saving.

- Maintenance Cost: This is zero. There is no painting, no re-grouting, no sealing.For a business owner, the TCO is the real number. A PVC wall that costs 30% more upfront but lasts 20 years with zero maintenance is a far cheaper investment than a drywall wall that needs to be repaired and repainted every 3 years.

Are Structural PVC Panels Sustainable?

This is a complex but important question for modern commercial builds.

- The Con: PVC is a petroleum-based plastic. It is not a "natural" or "green" material.

- The Pros:

- Durability: The most sustainable product is the one you do not have to replace. A 30-year lifespan is very sustainable.

- Recyclability: PVC is plastic #3 and is 100% recyclable at the end of its life.

- Low VOCs: They are a stable product and do not off-gas harmful VOCs like some paints and adhesives.

- You can read more on this topic in our sustainable PVC wall paneling guide.