WPC vs. PVC Wall Panels: The Honest Comparison (2026 Lab Test)

In our 20 years of manufacturing experience at Zhongshan Hengsu Decoration Materials, we have seen thousands of clients torn between WPC (Wood-Plastic Composite) and PVC (Polyvinyl Chloride). Most online guides regurgitate generic sales copy. This article is different. We are taking you inside our factory to look at the chemistry, the density, and the lived reality of installing these two distinct materials.

At a Glance: The Core Differences

WPC wall panels are the superior choice for living areas and bedrooms due to their acoustic insulation and matte, wood-like finish, whereas PVC panels dominate in bathrooms and commercial kitchens because they are 100% waterproof and cost-effective. While WPC offers a premium "solid wood" feel, PVC provides unmatched utility in high-moisture zones.

Table 1: The 2026 HSCS Decor Lab Comparison

| Feature | WPC (Wood-Plastic Composite) | PVC (Polyvinyl Chloride) | Winner |

| Core Composition | 60% Wood Fiber + 30% HDPE + Additives | 100% Polyvinyl Chloride Resin | Depends on Use |

| Water Resistance | Water-Resistant (Swells if unsealed) | Hydrophobic (100% Waterproof) | PVC |

| Impact Strength | High (Dense, Solid Feel) | Moderate (Can be brittle) | WPC |

| Fire Rating | Class B1 (Self-extinguishing) | Class B1 (Self-extinguishing) | Draw |

| Aesthetics | Matte, Natural Grain Texture | Glossy or "Printed" Texture | WPC |

| Best Application | Bedrooms, Living Rooms, Offices | Bathrooms, Kitchens, Hospitals | - |

1. Material Composition & "The Cut Test"

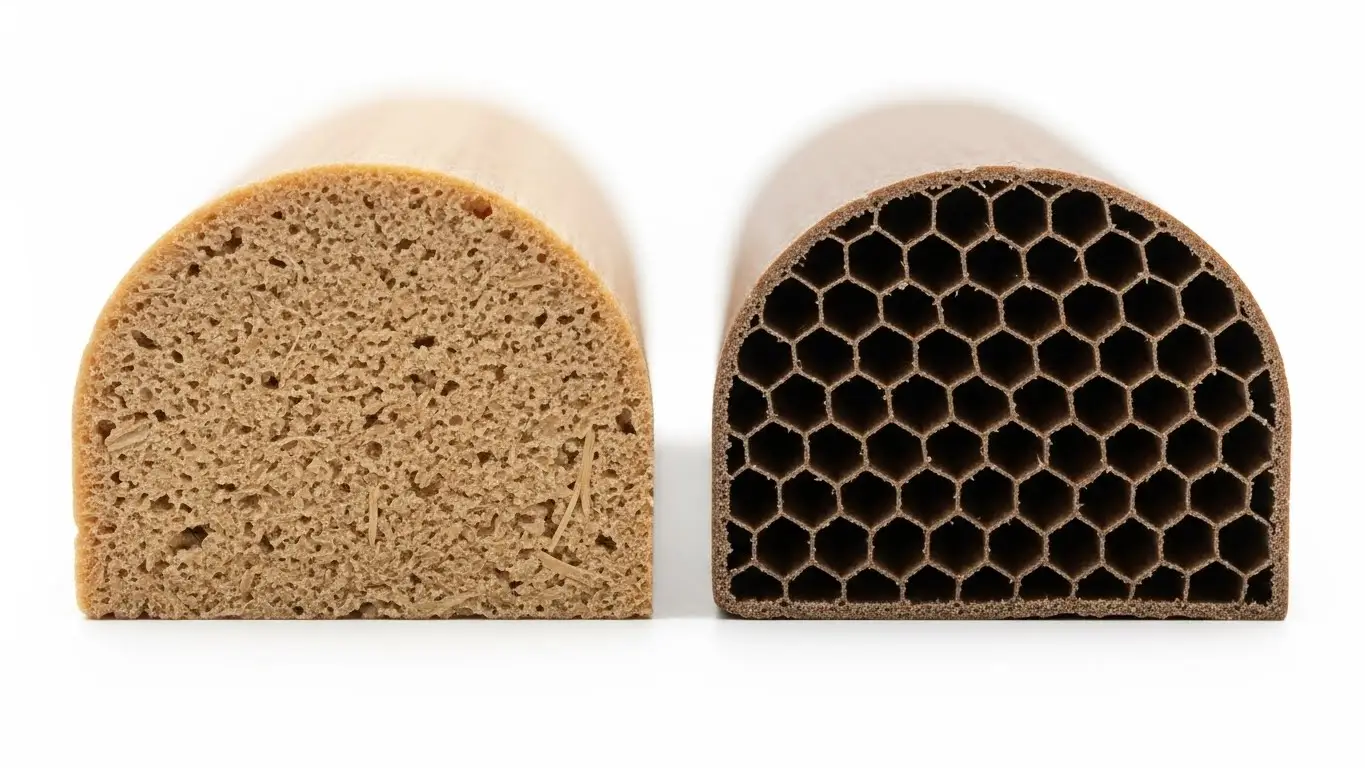

WPC wall panels are a hybrid material made by blending wood powder (bamboo or wood fiber) with thermoplastics, creating a dense, structural board that mimics timber. In contrast, PVC panels are synthetic polymers, often extruded with a hollow honeycomb structure to reduce weight while maintaining rigidity for vertical applications.

What is inside the core?

When we cut open our panels at the factory, the difference is audible. Cutting PVC sounds like slicing hard plastic—high-pitched and quick. Cutting WPC sounds like sawing through hardwood.

If you are wondering exactly what is WPC wall panel made of, it is primarily a mixture of wood fiber (often bamboo for sustainability) and thermoplastics. This gives it that heavy, "dead" sound when you knock on it, signaling quality to a potential homebuyer. PVC, being lighter and often hollow, can sound "clunky" if not adhered properly to the substrate.

For those looking for the next evolution in materials, we are also seeing a surge in bamboo charcoal wall panel technology. These hybrid boards offer the density of WPC with the waterproof benefits of PVC, effectively bridging the gap between the two.

2. Durability & Stress Tests (Lived Experience)

PVC wall panels are chemically inert, making them immune to rot, mold, and termites, which is why they are the industry standard for wet areas. WPC panels, while treated for durability, contain organic wood fibers that can eventually degrade if constantly submerged or exposed to harsh UV rays without a protective co-extrusion layer.

Impact & Scratch Resistance

In our internal "Key Test," we drag a jagged house key across both surfaces.

- The PVC Result: On standard glossy PVC, the scratch is immediately visible as a white line. The surface is smooth, so any imperfection catches the light.

- The WPC Result: Our fluted WPC panels hide the scratch. The matte texture and wood grain pattern camouflage minor damage, making it ideal for high-traffic hallways or commercial lobbies.

The Outdoor Verdict

A common question we get from clients is how long do WPC wall panels last outdoors. The answer lies in the coating. While standard interior WPC will fade under UV exposure, our exterior-grade co-extruded WPC can last 15-20 years. PVC, however, becomes brittle when exposed to direct sunlight and freezing temperatures over time, leading to cracking.

3. Installation & Acoustics

WPC wall panels require a more robust installation method, typically involving metal clips or screwing directly into a batten system due to their weight. PVC panels are lightweight and can often be installed using construction adhesive or a simple tongue-and-groove system, making them significantly faster and cheaper to install for DIY projects.

Sound Insulation (The Knock Test)

If sound dampening is a priority, WPC is the only logical choice. The density of the wood fiber absorbs sound waves, reducing echo in large rooms. PVC, particularly the hollow-core varieties, can actually reflect sound, making a room feel "noisier." For a master bedroom or home theater, we always recommend WPC or our Solid Wood Slat series.

Cutting and Fitting

Working with WPC requires standard woodworking tools. A chop saw with a fine-tooth blade gives the cleanest edge. If you are a DIYer, knowing how to cut WPC wall panels without chipping is crucial: always cut with the finished side facing up if using a hand saw, or down if using a circular saw, to prevent the veneer from tearing.

4. Cost Analysis 2026: Is WPC Worth It?

WPC wall panels generally cost 20-30% more upfront than standard PVC panels due to the raw material costs of wood fiber and the heavier manufacturing process. However, when calculating the Total Cost of Ownership (TCO) over 10 years, WPC often retains better value because it does not crack under impact and adds tangible resale value to a property.

- PVC: Low entry cost. Ideal for flipping houses, rental properties, or quick renovations where budget is the primary constraint.

- WPC: Higher investment. Best for "forever homes" or luxury commercial fit-outs where the look and feel of real wood are non-negotiable.

5. Final Verdict: Which One Should You Buy?

Choose PVC wall panels if you are renovating a bathroom, laundry room, or commercial kitchen where hygiene and waterproofing are critical. Choose WPC wall panels if you are designing a living room, bedroom, or office feature wall where you need the aesthetic warmth of wood, acoustic dampening, and a premium matte finish.

Decision Matrix

- Renovating a Shower? -> PVC (No risk of swelling).

- Building a Home Theater? -> WPC (Better acoustics).

- Tight Budget Rental? -> PVC (Cheaper, easier to replace).

- Luxury Hotel Lobby? -> WPC (High-end aesthetic).

Frequently Asked Questions

How do I clean and maintain WPC wall panels compared to PVC?

WPC panels require gentle cleaning using a soft cloth and mild soapy water to preserve their matte finish and prevent water spots. In contrast, PVC panels are non-porous and can withstand harsher chemical cleaners, making them easier to sanitize. For detailed steps, read our guide on how to clean and maintain WPC wall panels.

Can WPC panels be used in a bathroom?

Yes, but only in dry areas. WPC is water-resistant, not waterproof. You can use it for a vanity wall or powder room, but we do not recommend installing it inside a shower cubicle. For direct water contact, PVC or tile is the only safe option to prevent long-term swelling.

Do WPC panels expand and contract?

Yes, thermal expansion affects WPC slightly more than stone but less than solid wood. When installing, you must leave a small expansion gap (usually 1-2mm) at the joints or edges. This prevents the panels from warping during hot summers, especially in non-climate-controlled environments.

Is WPC environmentally friendly?

Yes, WPC is highly sustainable because it utilizes recycled plastics (HDPE) and waste wood fibers that would otherwise end up in landfills. At HSCS Decor, our WPC production process is designed to be low-waste, and the panels themselves are 100% recyclable at the end of their lifespan.